COMSOL has the best multiphysical simulation capabilities in my experience. Technical support from Elisa at TECHNIC as well as the engineers at COMSOL has been great.

COMSOL is an important part of our research in plasma physics. We use it in the design of plasma systems and it helps us to obtain a greater understanding of the underlying physics. We have always valued the quick support from TECHNIC and COMSOL and it has been a pleasure to work with them.

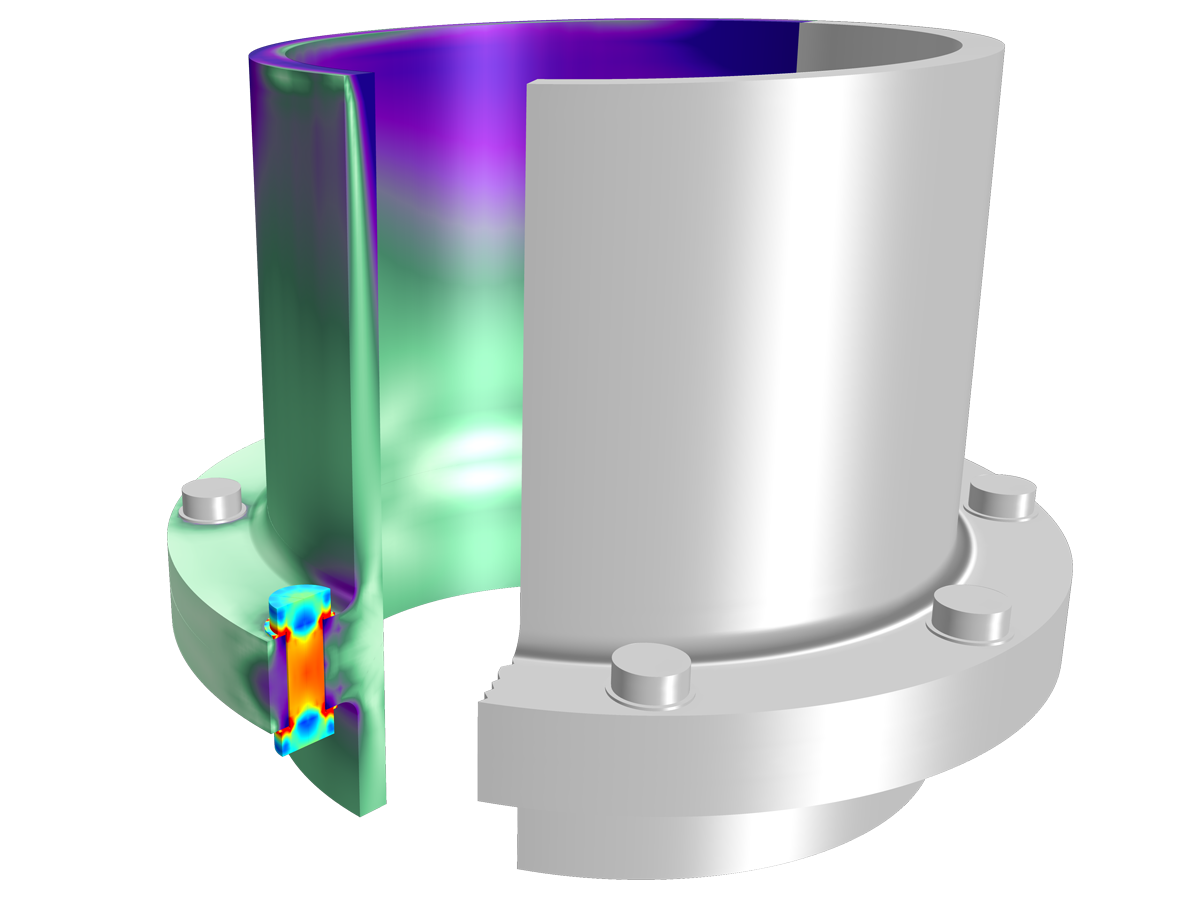

Comsol has become a valuable part of our design and decision making process. The exceptional flexibility and access to the physics and solvers in Comsol has allowed us to have deeper understanding on thermomechanical solutions. Technic and Comsol have always been quick and helpful to resolve any issues and provide helpful advice on their products.

At Scion we use COMSOL Multiphysics to understand energy processes, such as the interplay of non-linear solid mechanics and heat & mass transfer during biomass compaction, to design new or more efficient processes.

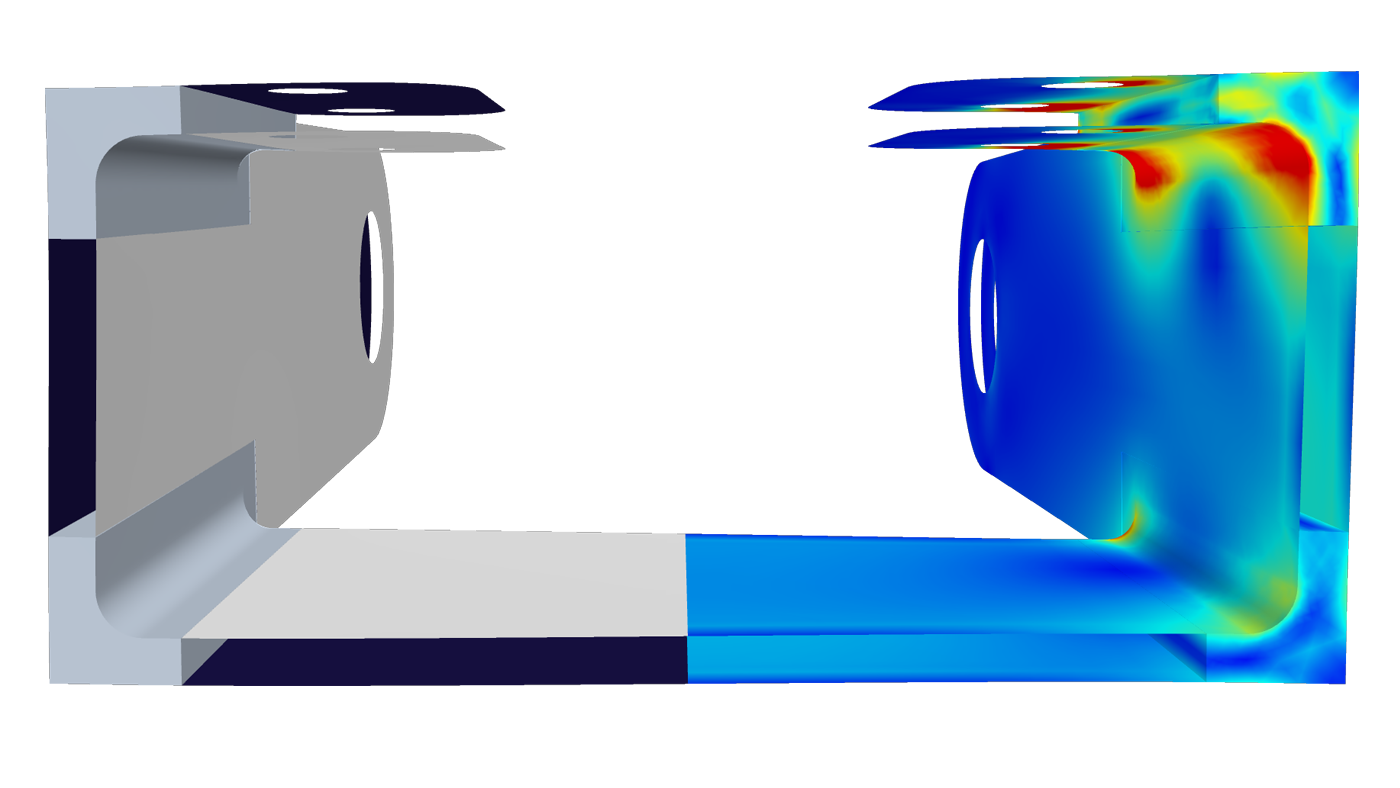

We use COMSOL Multiphysics to design the customised muffler. With it, we can simulate the insertion loss at different spectrum with different muffler designs.

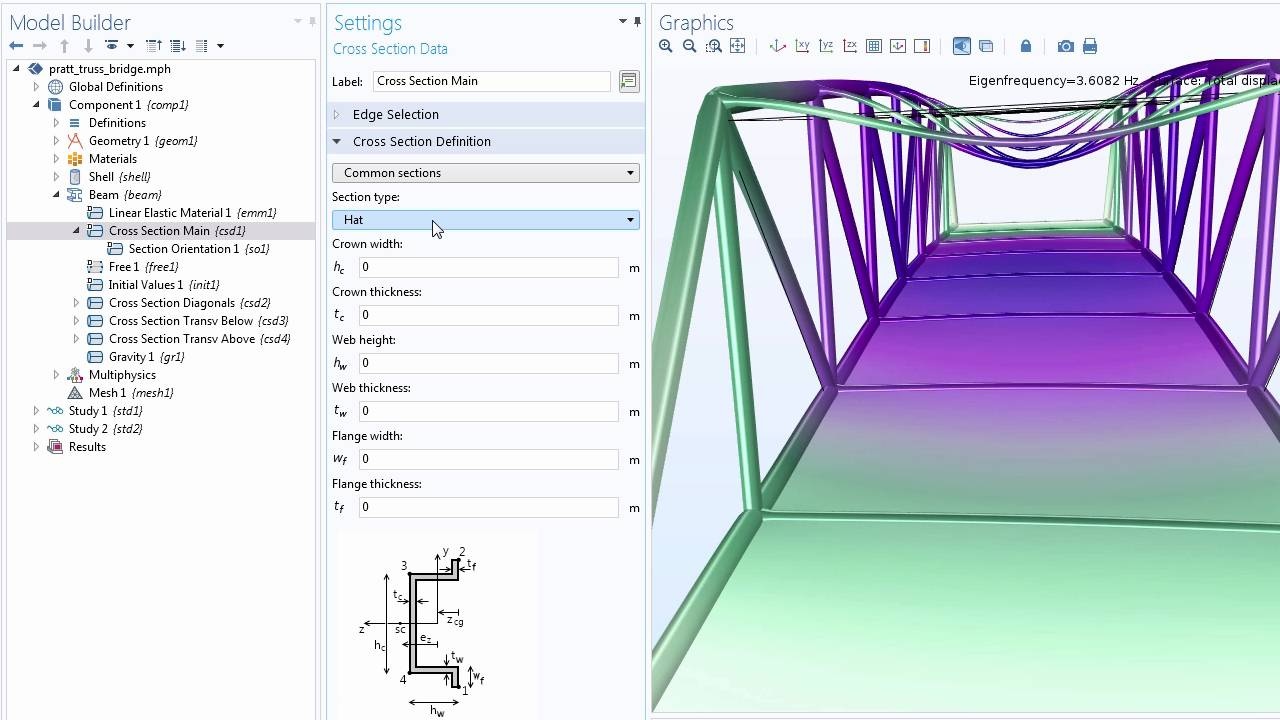

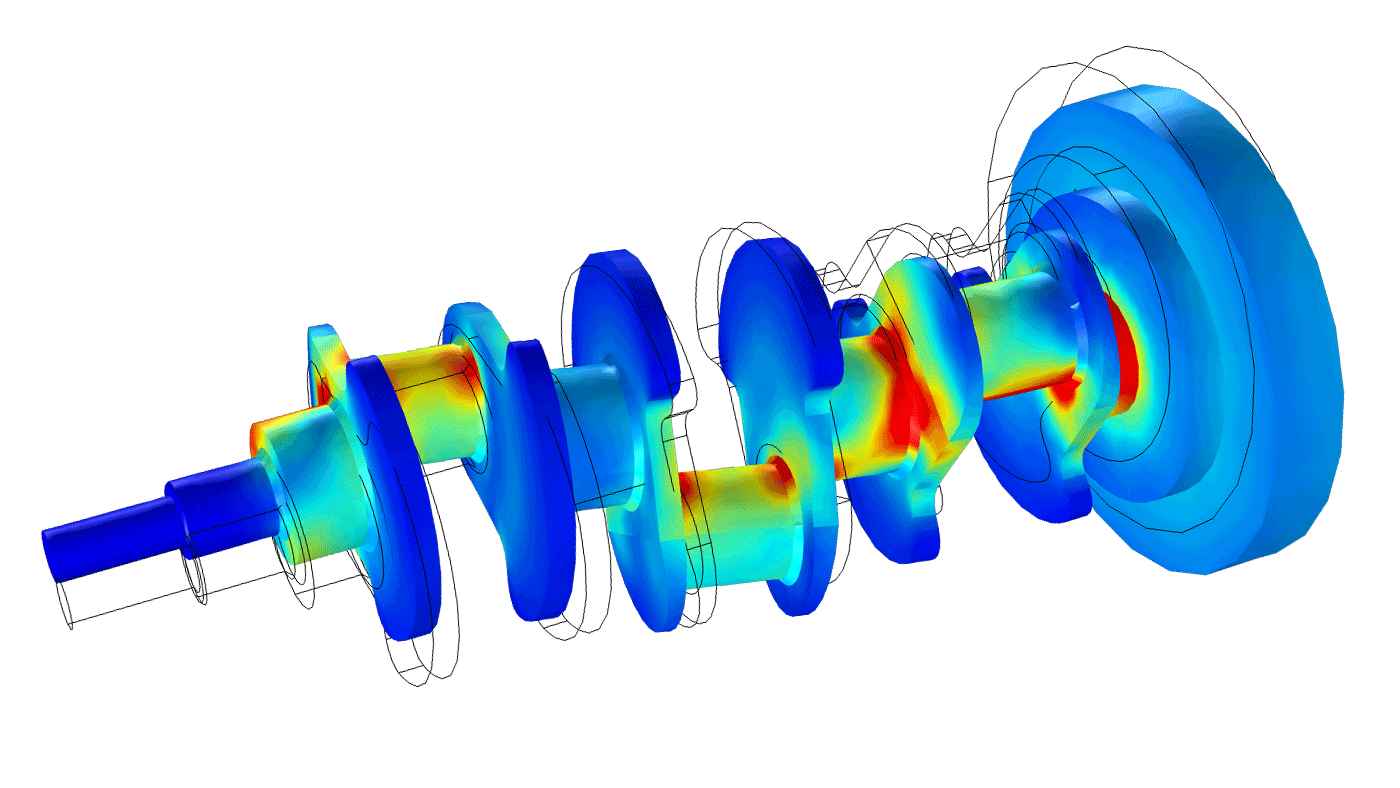

The Structural Mechanics Module is an add-on to the COMSOL Multiphysics® platform that brings you modelling tools and functionality tailored for analysing mechanical behaviour of solid structures. Application areas include mechanical engineering, civil engineering, geomechanics, biomechanics, and MEMS devices. Using the Structural Mechanics Module, you will be able to answer questions concerning, for example, stress and strain levels; deformations, stiffness, and compliance; natural frequencies; response to dynamic loads; and buckling instability, to name a few.

Combining the Structural Mechanics Module with other modules from the COMSOL® product suite allows for further extending your models to include heat transfer, electromagnetics, and fluid flow effects — all within one simulation environment.

The COMSOL Multiphysics® FEA software comes with predefined physics interfaces with specialised settings, making it easy to set up and run analyses. The Structural Mechanics Module includes both predefined material models to choose from and the ability to enter user-defined material models, depending on the nature of your analysis. You can also optimise the geometric dimensions, loads, and material properties of your designs with the Optimisation Module add-on.

View more details on what you can model with the Structural Mechanics Module below.

It is also possible to evaluate the cross section properties for arbitrary 2D cross sections and use them as inputs for beam analyses.

Additionally, the Structural Mechanics Module provides a Pipe Mechanics interface, with a specialised element for structural analysis of piping systems. When combined with the Pipe Flow Module, all types of fluid loads can be automatically applied to the pipe system. Lastly, you can model slender structures that can only sustain axial forces (trusses). These elements can also be used for modelling sagging cables and reinforcements.

The Structural Mechanics Module provides linear elastic, viscoelastic, and piezoelectric material models, but you can also access nonlinear materials by adding the Nonlinear Structural Materials Module or the Geomechanics Module.

You have many possibilities to extend the existing material models or create your own:

The material models can also accommodate thermal expansion, hygroscopic swelling, initial stresses and strains, as well as several types of damping. Material properties can be isotropic, orthotropic, or fully anisotropic.

The Nonlinear Structural Materials Module and the Geomechanics Module extend the capabilities of the Structural Mechanics Module with a wide range of nonlinear material models. Seamlessly integrated in the COMSOL Multiphysics® GUI, these add-on products can be used for pure nonlinear mechanical analyses or combined with other add-ons for multiphysics analyses. In all, you will find more than 75 different material models for structural mechanics.

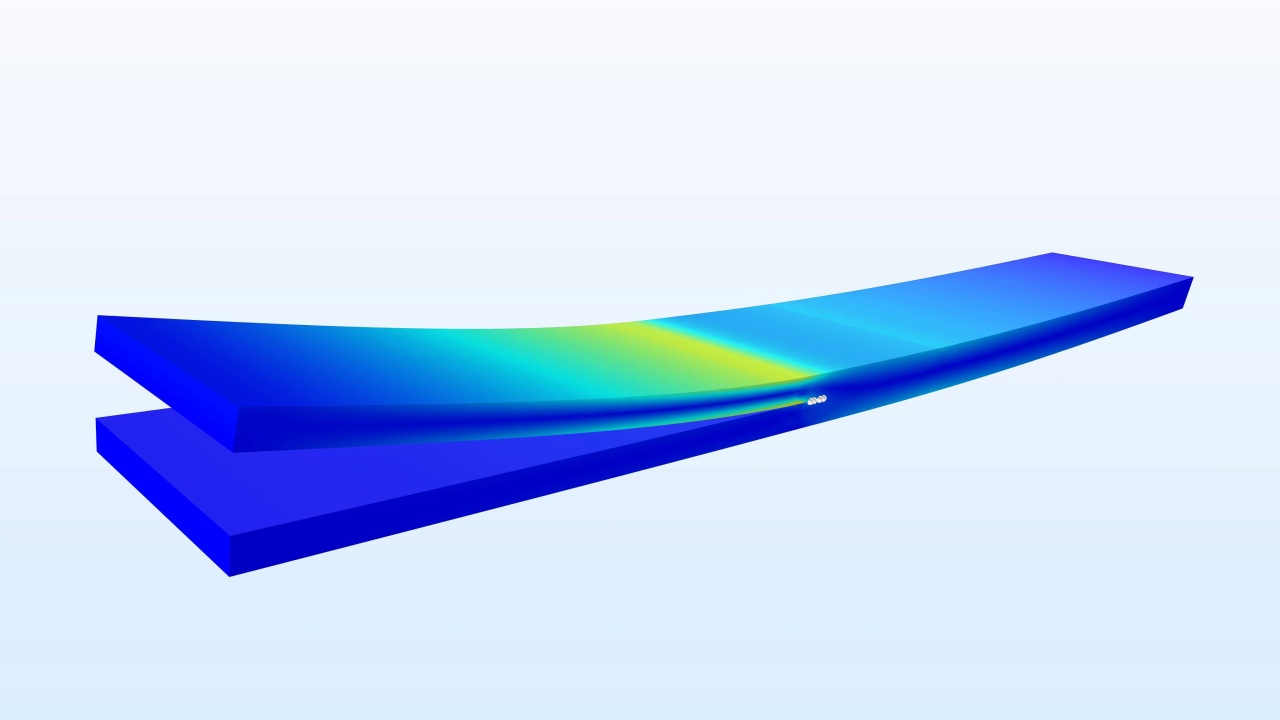

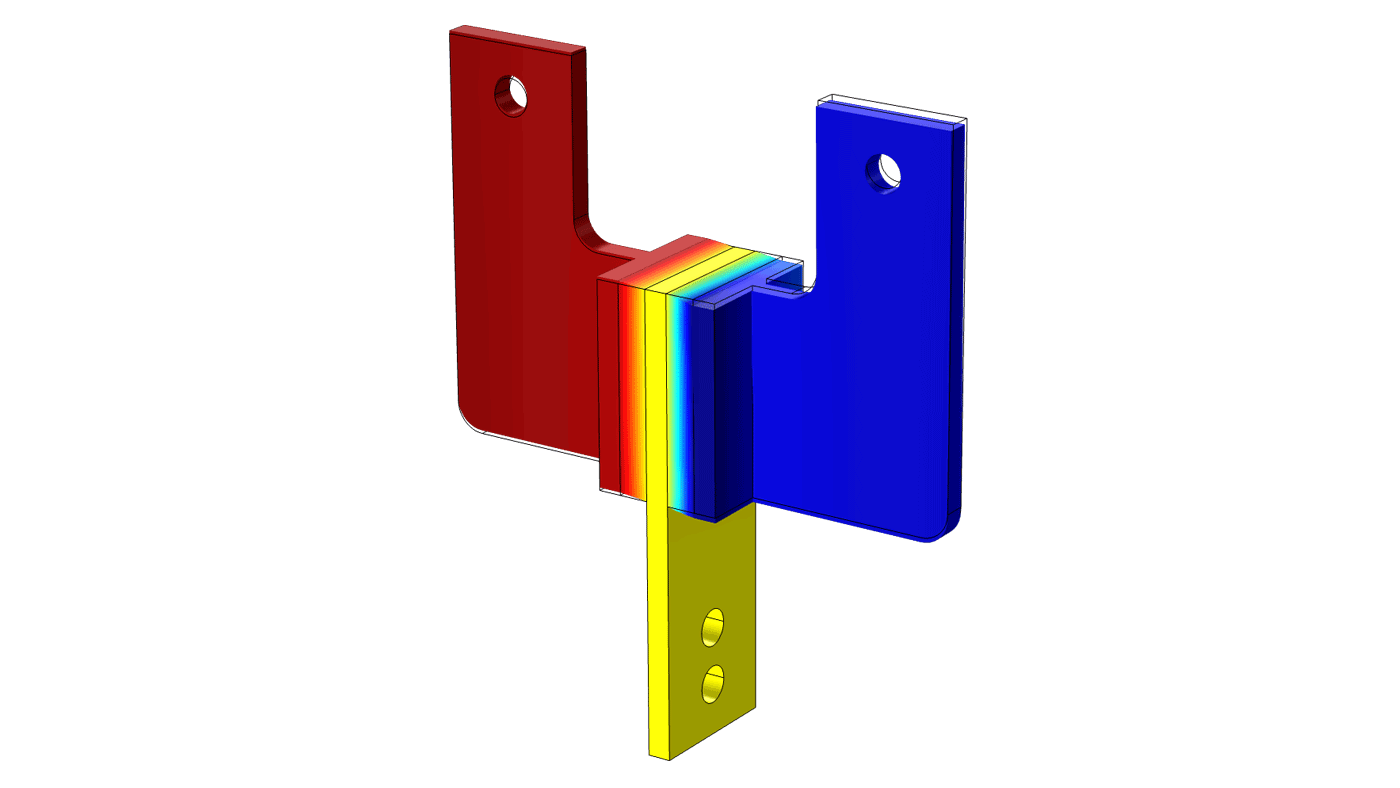

You can also analyse thin, layered structures with the addition of the Composite Materials Module. This add-on module employs specialised layered material technology with two variations, layerwise theory and equivalent single layer theory, which each provide their own benefits. This module can be used to model layered composite materials such as fiber-reinforced plastic, laminated plates, and sandwich panels found in aircraft components, spacecraft components, wind turbine blades, automobile components, boat hulls, and more.

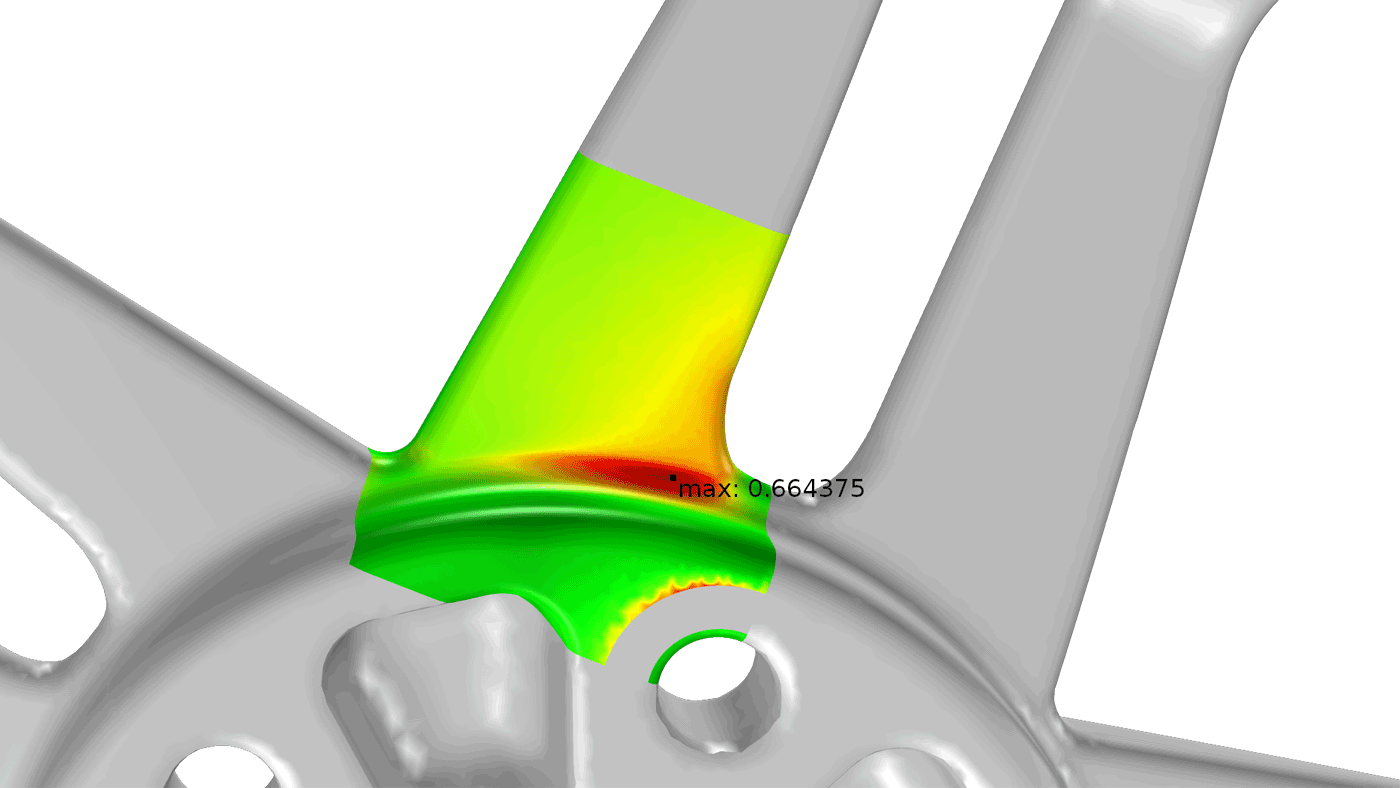

You can compute the fatigue life of structures using the Fatigue Module, which is available as an add-on to the Structural Mechanics Module. The Fatigue Module allows for a variety of fatigue analyses including strain-, stress-, and energy-based fatigue and is completely integrated with the COMSOL Multiphysics® simulation environment.

Fatigue analyses:

Analyse multibody systems with the Multibody Dynamics Module. It provides an extensive set of tools for simulating mixed systems of flexible and rigid bodies. Together with the Structural Mechanics Module, couplings to the Solid Mechanics, Shell, and Beam interfaces give access to the full range of structural mechanics features.

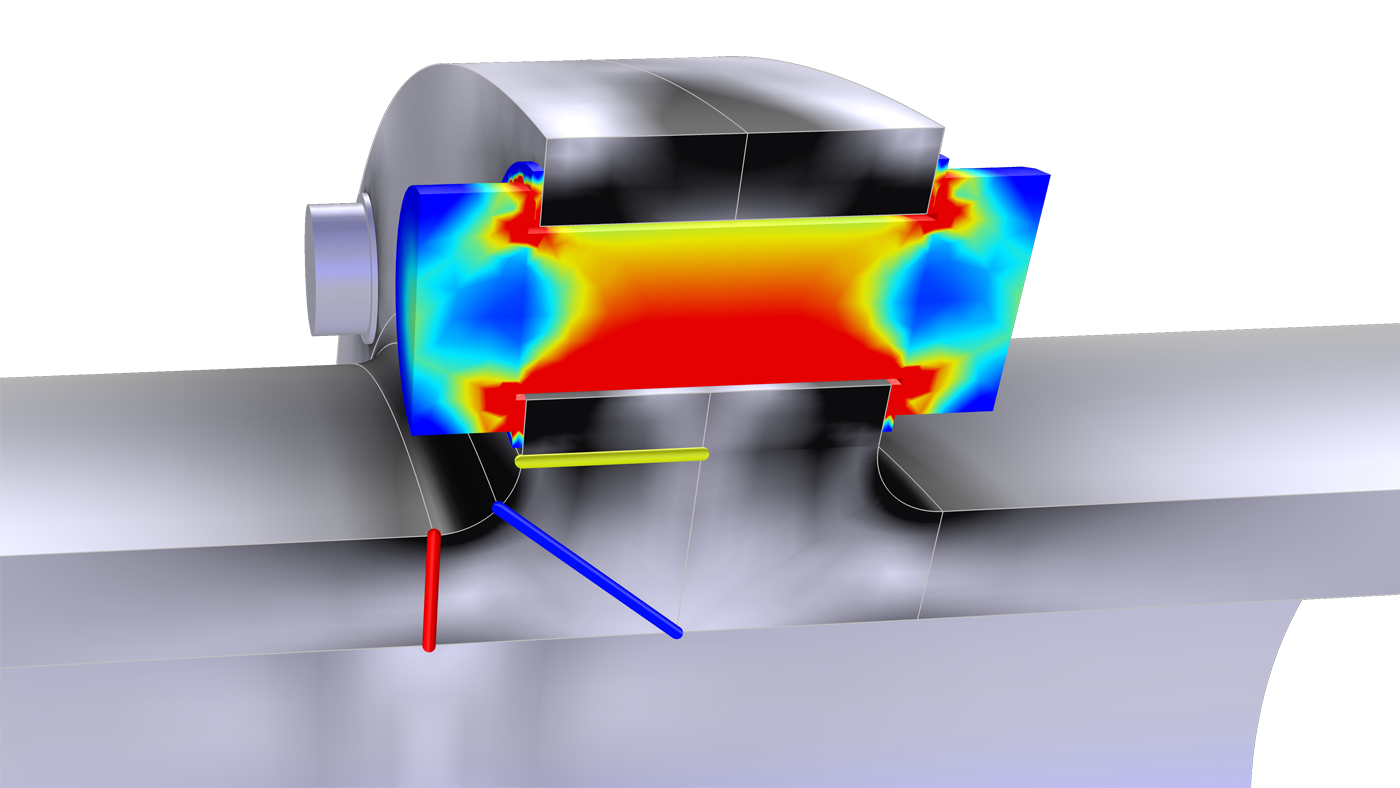

Add the Rotordynamics Module to model components and parts in rotating machines where asymmetries and rotation can lead to instabilities and damaging resonances.

Import a variety of industry-standard CAD formats into COMSOL Multiphysics® for simulation analysis using the CAD Import Module. Available features include options to repair and clean up your CAD geometry to prepare it for meshing and analysis, as well as access to the Parasolid® geometry kernel for advanced solid options. The Design Module also includes these features, plus it lets you perform the following 3D CAD operations: loft, fillet, chamfer, midsurface, and thicken.

Choose from a line of interfacing products that let you import designs from CAD software into COMSOL Multiphysics® to perform advanced simulations. With the LiveLink™ products, you can keep the parameterisation of the CAD-native model so that you can perform parametric studies and optimisation in the COMSOL® software, without having to reconstruct model parameters.

You can also simultaneously update geometry parameters in both the CAD system and COMSOL Multiphysics®, as well as perform parametric sweeps and optimisation over several different modeling parameters.

Available for use with:

Study the interaction between a fluid and solid structure, including both fluid pressure and viscous forces. The deformations of the structure, which act as a boundary condition on the fluid, can be arbitrarily large. The fluid-structure interaction can occur between parts, where the fluid and structures share a mesh, or assemblies, where there does not have to be a common boundary with a shared mesh.

Simulate thermal stress and thermoelastic damping with specialised multiphysics couplings. The structure’s material properties can also depend on the temperature field. Contact stresses can affect not only the mechanical solution, but also the heat flux through a contact surface.

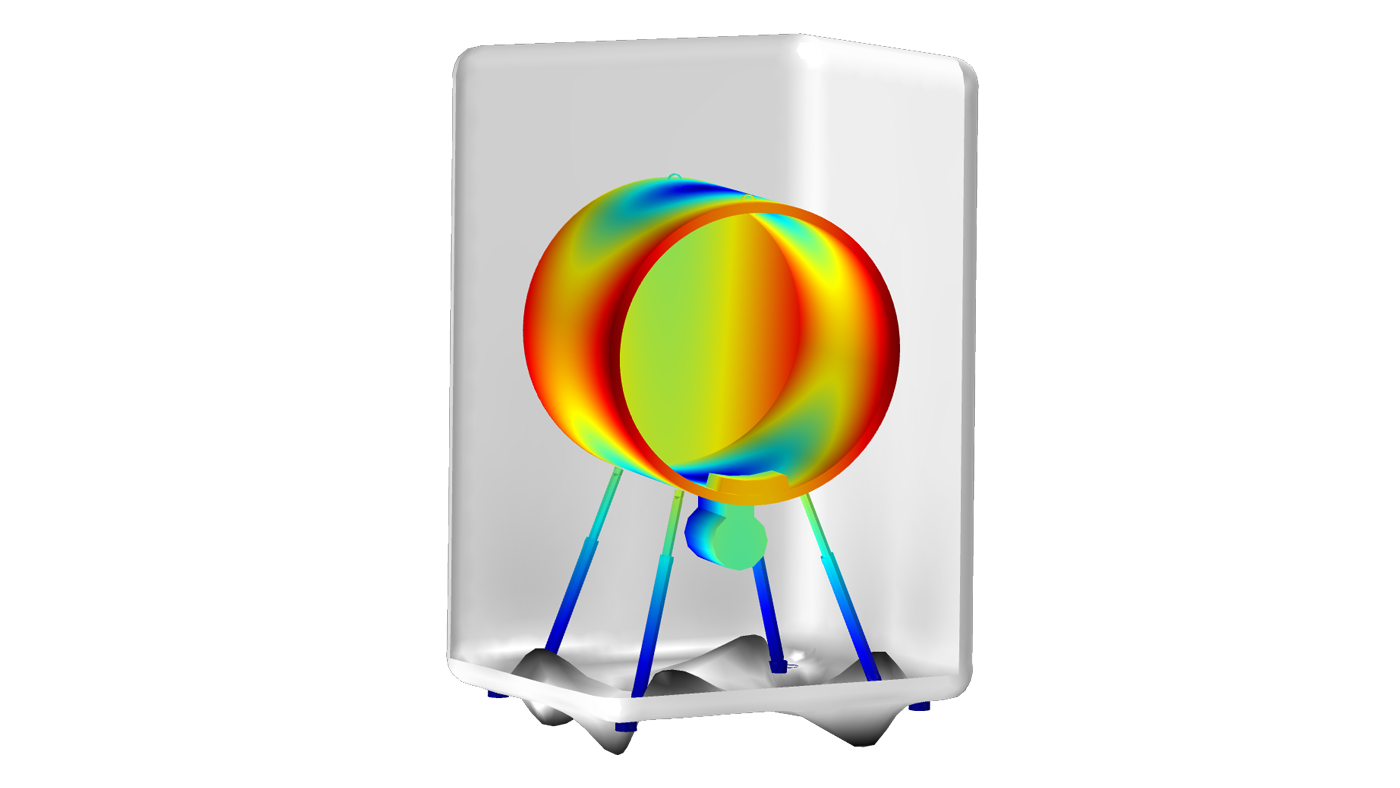

Investigate acoustic-structure interaction; vibration; acoustic-shell, solid-acoustic, and piezo-acoustic interactions; and elastic wave propagation by adding the Acoustics Module.

Add the Subsurface Flow Module or Porous Media Flow Module to enhance the solid mechanics interfaces with poroelasticity and porous media flow.

Piezoelectric devices can be accurately modeled using a built-in coupling between the Solid Mechanics and Electrostatics interfaces. Material properties for many popular piezoelectric materials are available.

Combine the AC/DC Module with the Structural Mechanics Module to couple solid mechanics and magnetic physics to model a wide range of sensors and actuators, based on the principles of magnetostriction.

Add the MEMS Module for structural simulations that are specific to MEMS. The built-in couplings make it easy to analyse piezoresistivity, electromechanical deflection due to electrostatic forces, and electrostriction.

Combine the Structural Mechanics Module with the RF Module, Wave Optics Module, or Ray Optics Module for analyses where mechanical deformation and stress affect the performance of RF, microwave, or optical devices.

Combine the AC/DC Module with the Structural Mechanics Module to add electromagnetic effects to your structural analyses, such as deformation due to electromagnetic forces, thermal expansion from Joule heating, and electro-thermo-mechanical contact.

Think of the time and energy you would be able to devote to new projects if you did not have to run repetitious simulation tests for other people on your team. With the Application Builder, included in COMSOL Multiphysics®, you can build simulation applications that further simplify the simulation workflow by enabling you to restrict the inputs and control the outputs of your model so that your colleagues can run their own analyses.

With specialised applications, you can easily change a design parameter, such as a geometrical dimension or material property, and test it as many times as you need without having to rerun the entire simulation. You can use applications to run your own tests more quickly or distribute applications to other members of your team to run their own tests, further freeing up your time and resources for other projects.

The process is simple:

You can expand the capabilities of simulation throughout your team, organisation, classroom, or customer base by building and using simulation applications.

In order to fully evaluate whether or not the COMSOL Multiphysics® software will meet your requirements, you need to contact us. By talking to one of our sales representatives, you will get personalised recommendations and fully documented examples to help you get the most out of your evaluation and guide you to choose the best license option to suit your needs.

Fill in your contact details and any specific comments or questions, and submit. You will receive a response from a sales representative within one business day.