COMSOL has the best multiphysical simulation capabilities in my experience. Technical support from Elisa at TECHNIC as well as the engineers at COMSOL has been great.

COMSOL is an important part of our research in plasma physics. We use it in the design of plasma systems and it helps us to obtain a greater understanding of the underlying physics. We have always valued the quick support from TECHNIC and COMSOL and it has been a pleasure to work with them.

Comsol has become a valuable part of our design and decision making process. The exceptional flexibility and access to the physics and solvers in Comsol has allowed us to have deeper understanding on thermomechanical solutions. Technic and Comsol have always been quick and helpful to resolve any issues and provide helpful advice on their products.

At Scion we use COMSOL Multiphysics to understand energy processes, such as the interplay of non-linear solid mechanics and heat & mass transfer during biomass compaction, to design new or more efficient processes.

We use COMSOL Multiphysics to design the customised muffler. With it, we can simulate the insertion loss at different spectrum with different muffler designs.

The Polymer Flow Module is an add-on to COMSOL Multiphysics that is used for defining and solving problems involving non-Newtonian fluids with viscoelastic, thixotropic, shear thickening, or shear thinning properties. You can account for the properties of the fluids as a function of temperature and composition to model cure and polymerisation. In combination with other modules in COMSOL Multiphysics, you can also model fully coupled and time-dependent fluid-structure interactions.

Non-Newtonian fluids are found in a great variety of processes in the polymer, food, pharmaceutical, cosmetics, household, and fine chemicals industries. Examples of these fluids are coatings, paints, yogurt, ketchup, colloidal suspensions, aqueous suspensions of drugs, lotions, creams, shampoo, suspensions of peptides and proteins, to mention a few. Modelling and simulation can be used to design and optimise processes where these fluids are involved, ensuring high-quality products for the end user.

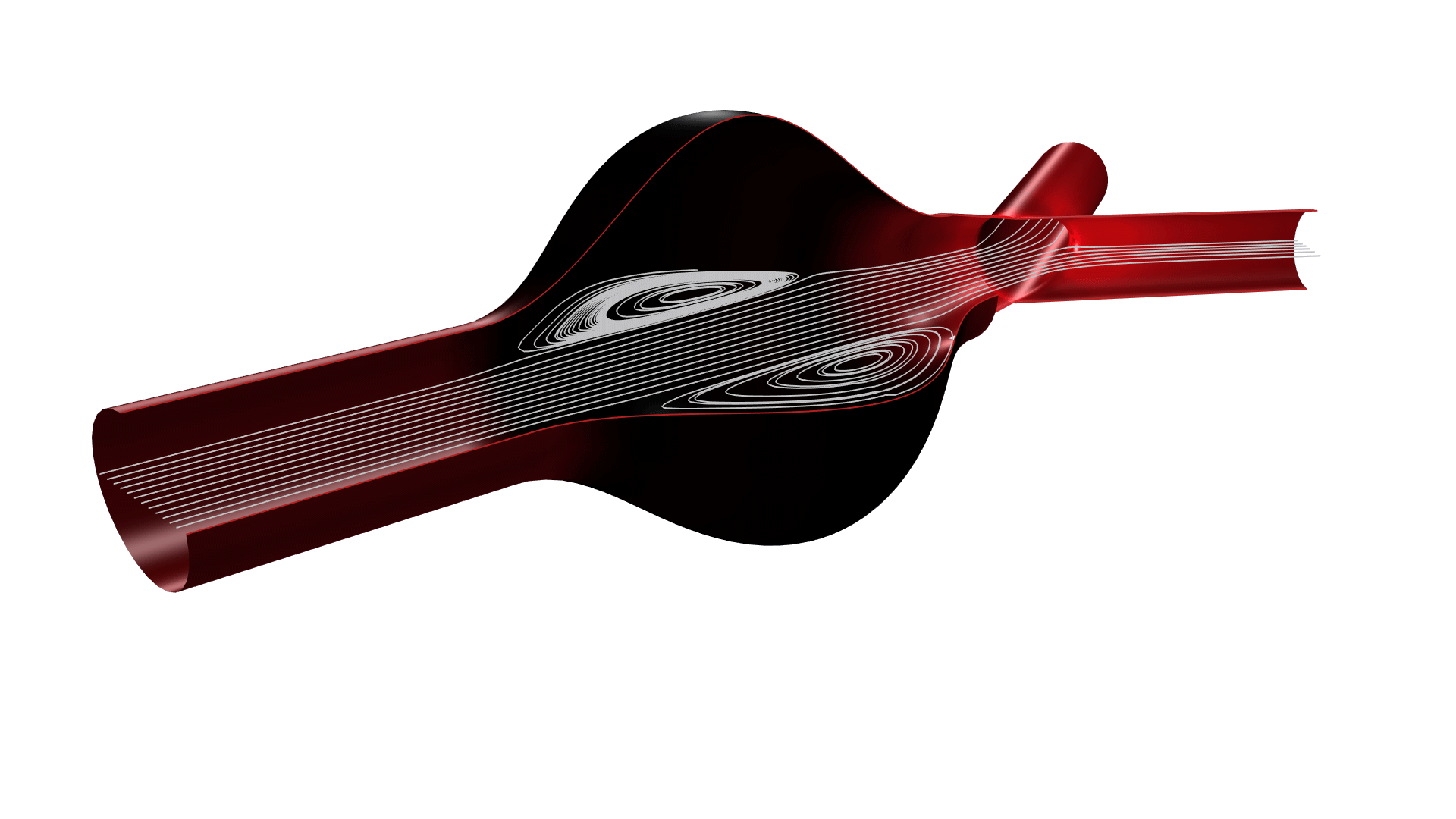

Viscoelastic fluid models account for the elasticity in these types of fluids. As the fluid is deformed, there is a certain amount of force that works toward returning the fluid to its undeformed state. Important aspects of modelling are to estimate the deformation of the fluid with time, that is the shape of the air–liquid interface, the local forces on the surfaces that may interact with these fluids, and the pressure losses in a system where the fluid flow occurs. Typical examples of these fluids are polymer melts, paints, and suspensions of proteins.

Colloidal suspensions may exhibit shear thickening behaviour, where viscosity increases substantially with shear rate. Other suspensions may be shear thinning, for example syrups and ketchup, where the viscosity decreases with shear rate. Thixotropic fluids also have a time dependency, where the viscosity decreases with the duration of the shear rate. The models describing these fluids are all inelastic, but they describe highly non-Newtonian behaviour. The purpose of modelling and simulation is similar to that for viscoelastic fluids above: estimate the shape of the air–liquid interface, the local forces on the surfaces that may interact with these fluids, and the pressure losses in a system where the fluid flow occurs. Additionally, the dependency on temperature and composition may be important for the design of manufacturing processes, for example, with the curing of rubber melts.

The Polymer Flow Module features a variety of viscoelastic fluid models. These models differ in the constitutive relations describing the deformation and the forces caused by the fluid's deformation. The Oldroyd-B model uses a linear relation, which can be described as a suspension of Hookean springs in a Newtonian solvent, while the others describe nonlinear elastic effects and shear thinning.

In addition to the viscoelastic models, the Polymer Flow Module features a wide range of inelastic non-Newtonian models. Many of the models are generic, used to describe shear thinning and shear thickening. For more specific applications, there are models for viscoplastic and thixotropic fluids.

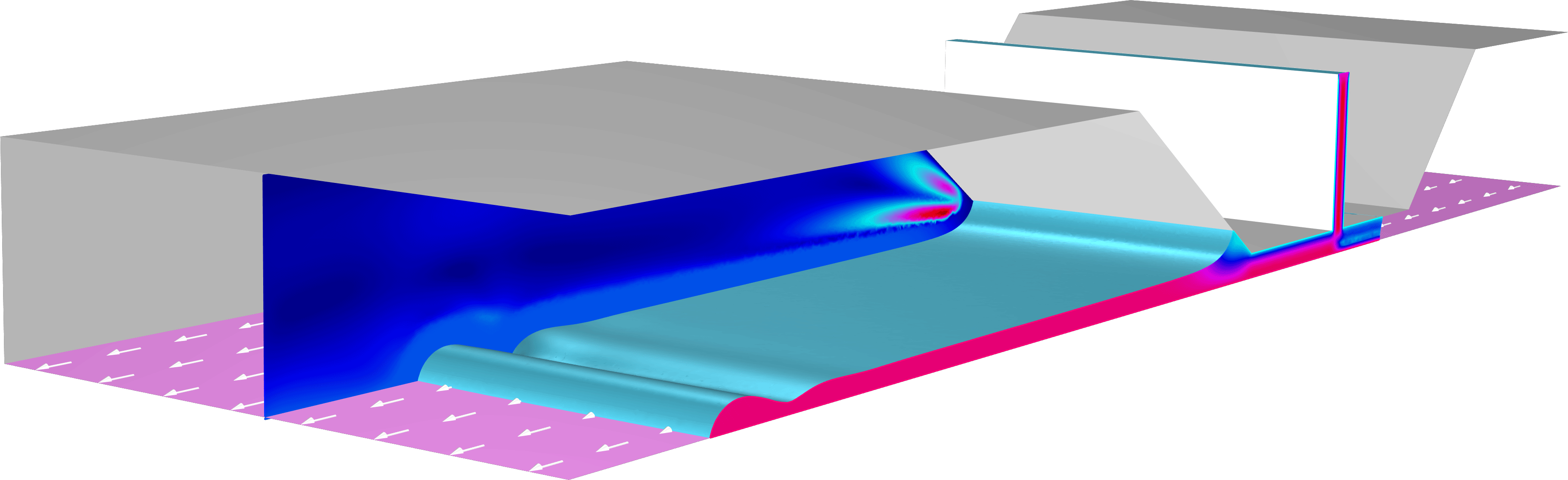

To make it possible to model the liquid–air interface when simulating coatings, free surfaces, and mold filling, the Polymer Flow Module includes three different separated multiphase flow models based on surface tracking methods. The Level Set method tracks the interface position by solving a transport equation for the level-set function. The Phase Field method tracks the interface position by solving two transport equations for the phase field variable and the mixing energy density. The Moving Mesh method tracks the interface position with a mesh that changes shape.

A common method of polymer extrusion and mould filling is to melt the rubber or polymer mixture. The mixture is then allowed to cure inside the mould. The Polymer Flow Module includes the thermal models required to model these processes: the Arrhenius, Williams–Landel–Ferry, and Exponential models are all available.

In order to fully evaluate whether or not the COMSOL Multiphysics® software will meet your requirements, you need to contact us. By talking to one of our sales representatives, you will get personalised recommendations and fully documented examples to help you get the most out of your evaluation and guide you to choose the best license option to suit your needs.

Fill in your contact details and any specific comments or questions, and submit. You will receive a response from a sales representative within one business day.