COMSOL has the best multiphysical simulation capabilities in my experience. Technical support from Elisa at TECHNIC as well as the engineers at COMSOL has been great.

COMSOL is an important part of our research in plasma physics. We use it in the design of plasma systems and it helps us to obtain a greater understanding of the underlying physics. We have always valued the quick support from TECHNIC and COMSOL and it has been a pleasure to work with them.

Comsol has become a valuable part of our design and decision making process. The exceptional flexibility and access to the physics and solvers in Comsol has allowed us to have deeper understanding on thermomechanical solutions. Technic and Comsol have always been quick and helpful to resolve any issues and provide helpful advice on their products.

At Scion we use COMSOL Multiphysics to understand energy processes, such as the interplay of non-linear solid mechanics and heat & mass transfer during biomass compaction, to design new or more efficient processes.

We use COMSOL Multiphysics to design the customised muffler. With it, we can simulate the insertion loss at different spectrum with different muffler designs.

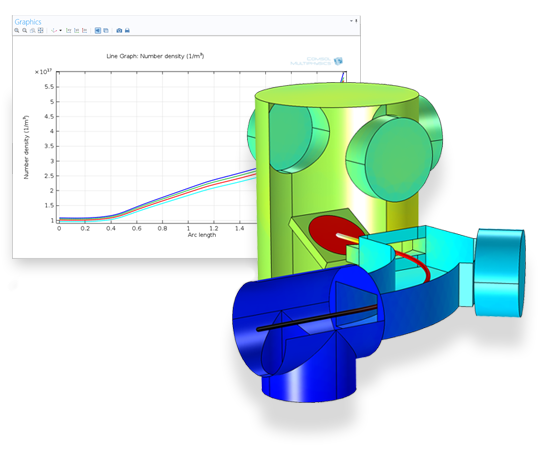

Vacuum engineers and scientists use the Molecular Flow Module to design vacuum systems and to understand and predict low-pressure gas flows. The use of simulation tools in the design cycle has become more widespread as these tools improve understanding, reduce prototyping costs, and speed up development. Vacuum systems are usually expensive to prototype. Therefore, an increased use of simulation in the design process can result in substantial cost savings. The gas flows that occur inside vacuum systems are described by different physics than conventional fluid flow problems. At low pressures, the mean free path of the gas molecules becomes comparable to the size of the system and gas rarefaction becomes important. Flow regimes are categorised quantitatively via the Knudsen number (Kn), which represents the ratio of the molecular mean free path to the flow geometry size for gases:

While the Microfluidics Module is used for modelling slip and continuum flows, the Molecular Flow Module is designed for accurately simulating flows in the free molecular flow regime. Historically, flows in this regime have been modelled by the direct simulation Monte Carlo (DSMC) method. This computes the trajectories of large numbers of randomised particles through the system, but introduces statistical noise into the modelling process. For low-velocity flows, such as those encountered in vacuum systems, the noise introduced by DSMC renders the simulations unfeasible.

The Molecular Flow Module is designed to offer previously unavailable simulation capabilities for the accurate modelling of low-pressure gas flows in complex geometries. It is ideal for the simulation of vacuum systems, including those used in semiconductor processing, particle accelerators, and mass spectrometers. Small channel applications (e.g., shale gas exploration and flow in nanoporous materials) may also be addressed. The Molecular Flow Module uses the angular coefficient method to simulate steady-state free molecular flows, allowing the molecular flux, pressure, number density, and heat flux to be computed on surfaces. The number density can be reconstructed on domains, surfaces, edges, and points from the molecular flux on the surrounding surfaces. You can model isothermal and nonisothermal molecular flows and calculate the heat flux contribution from the gas molecules.

In an ion implanter, the average number density of outgassing molecules along the beam path is used as a figure of merit to evaluate the design. It must be computed as a function of wafer angle, with rotation about one axis.

In order to fully evaluate whether or not the COMSOL Multiphysics® software will meet your requirements, you need to contact us. By talking to one of our sales representatives, you will get personalised recommendations and fully documented examples to help you get the most out of your evaluation and guide you to choose the best license option to suit your needs.

Fill in your contact details and any specific comments or questions, and submit. You will receive a response from a sales representative within one business day.