COMSOL has the best multiphysical simulation capabilities in my experience. Technical support from Elisa at TECHNIC as well as the engineers at COMSOL has been great.

COMSOL is an important part of our research in plasma physics. We use it in the design of plasma systems and it helps us to obtain a greater understanding of the underlying physics. We have always valued the quick support from TECHNIC and COMSOL and it has been a pleasure to work with them.

Comsol has become a valuable part of our design and decision making process. The exceptional flexibility and access to the physics and solvers in Comsol has allowed us to have deeper understanding on thermomechanical solutions. Technic and Comsol have always been quick and helpful to resolve any issues and provide helpful advice on their products.

At Scion we use COMSOL Multiphysics to understand energy processes, such as the interplay of non-linear solid mechanics and heat & mass transfer during biomass compaction, to design new or more efficient processes.

We use COMSOL Multiphysics to design the customised muffler. With it, we can simulate the insertion loss at different spectrum with different muffler designs.

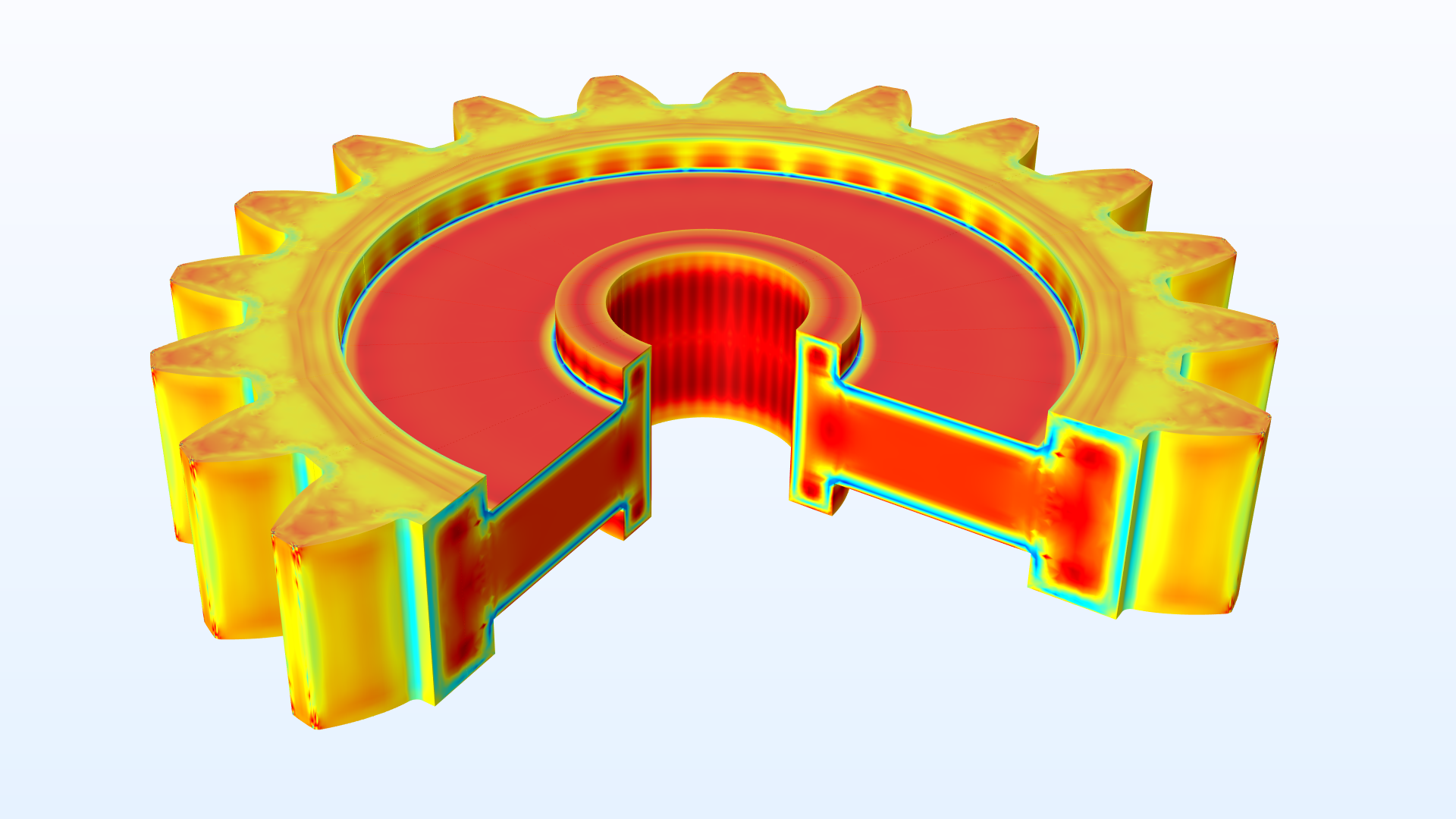

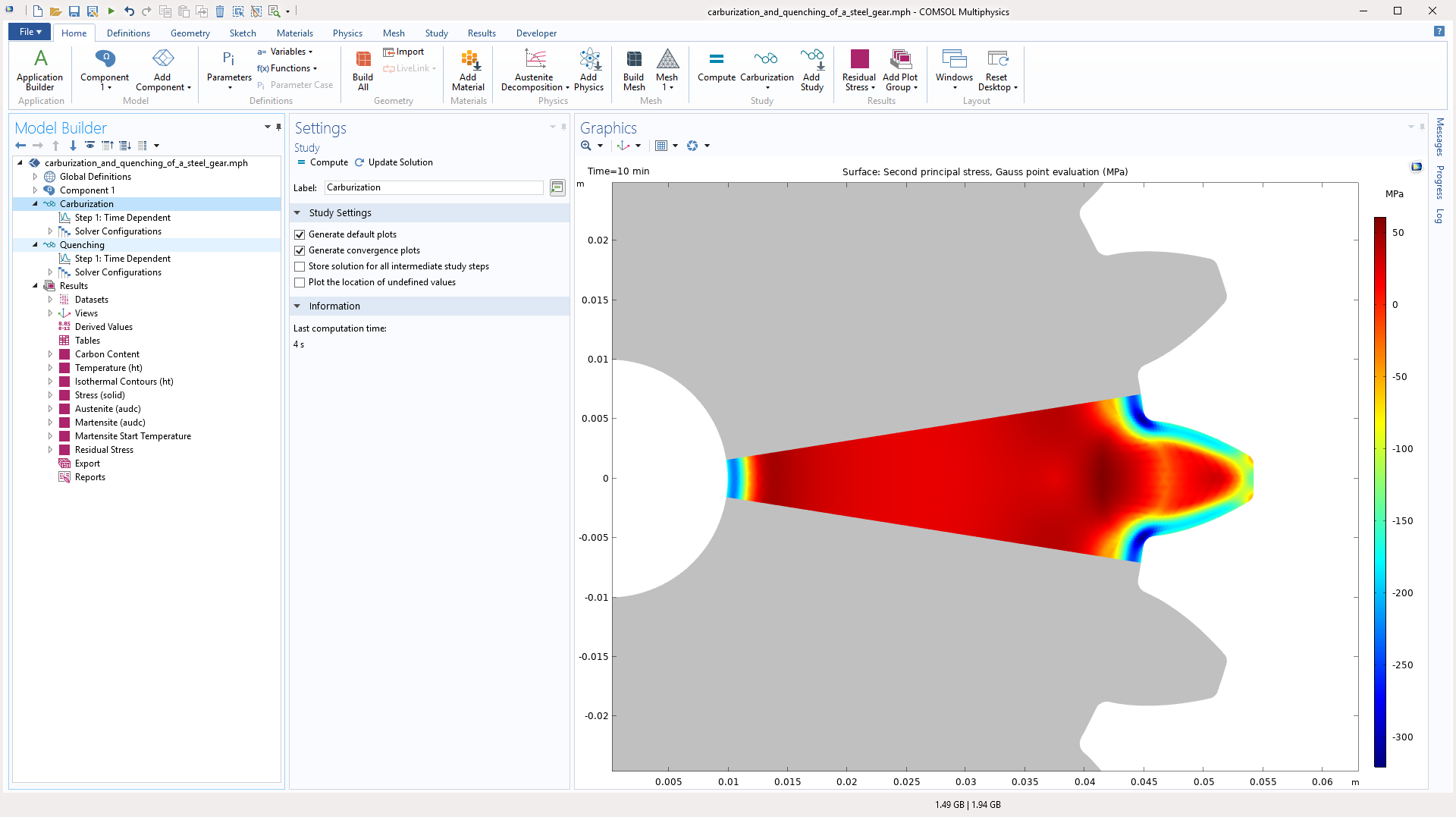

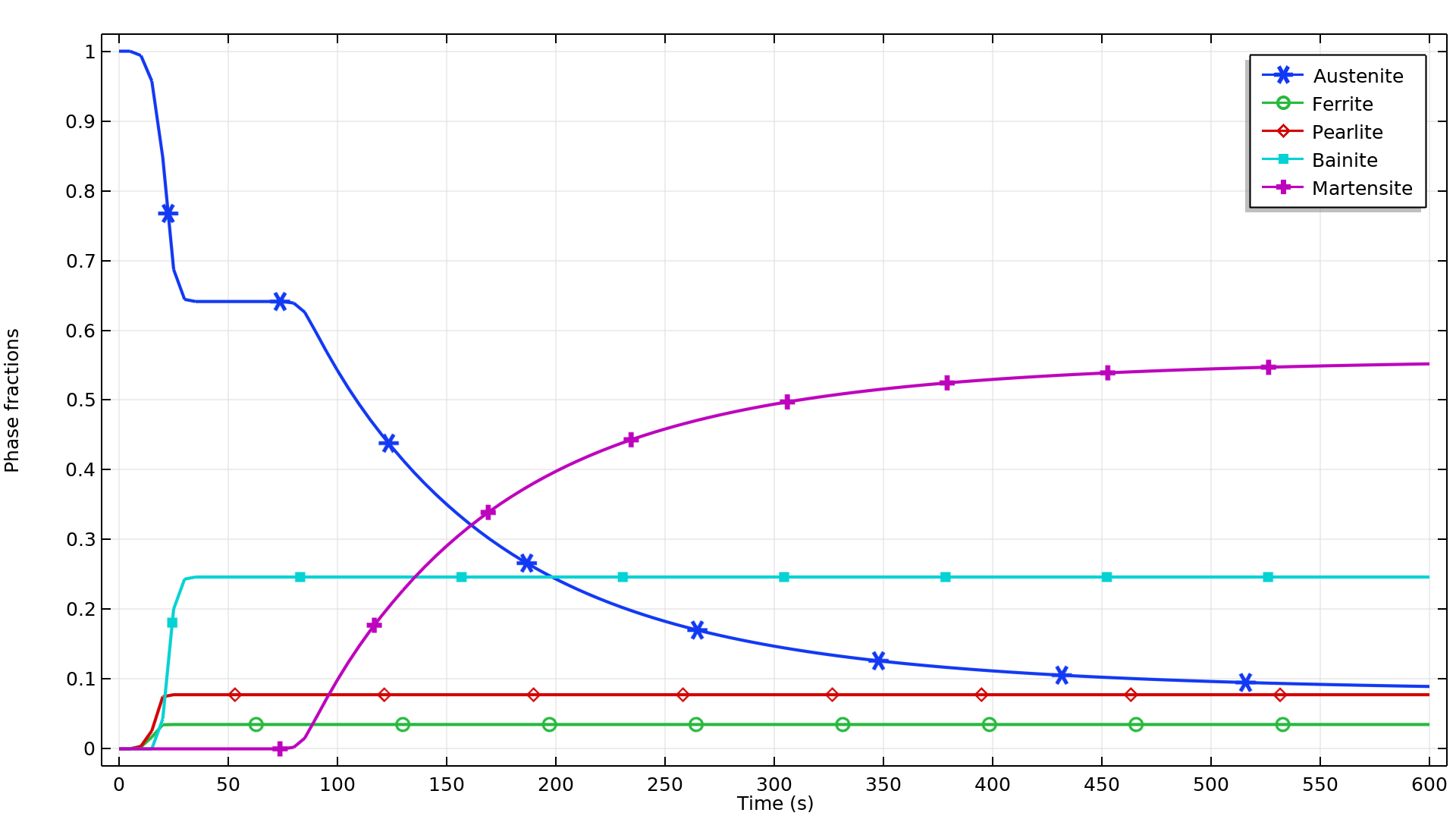

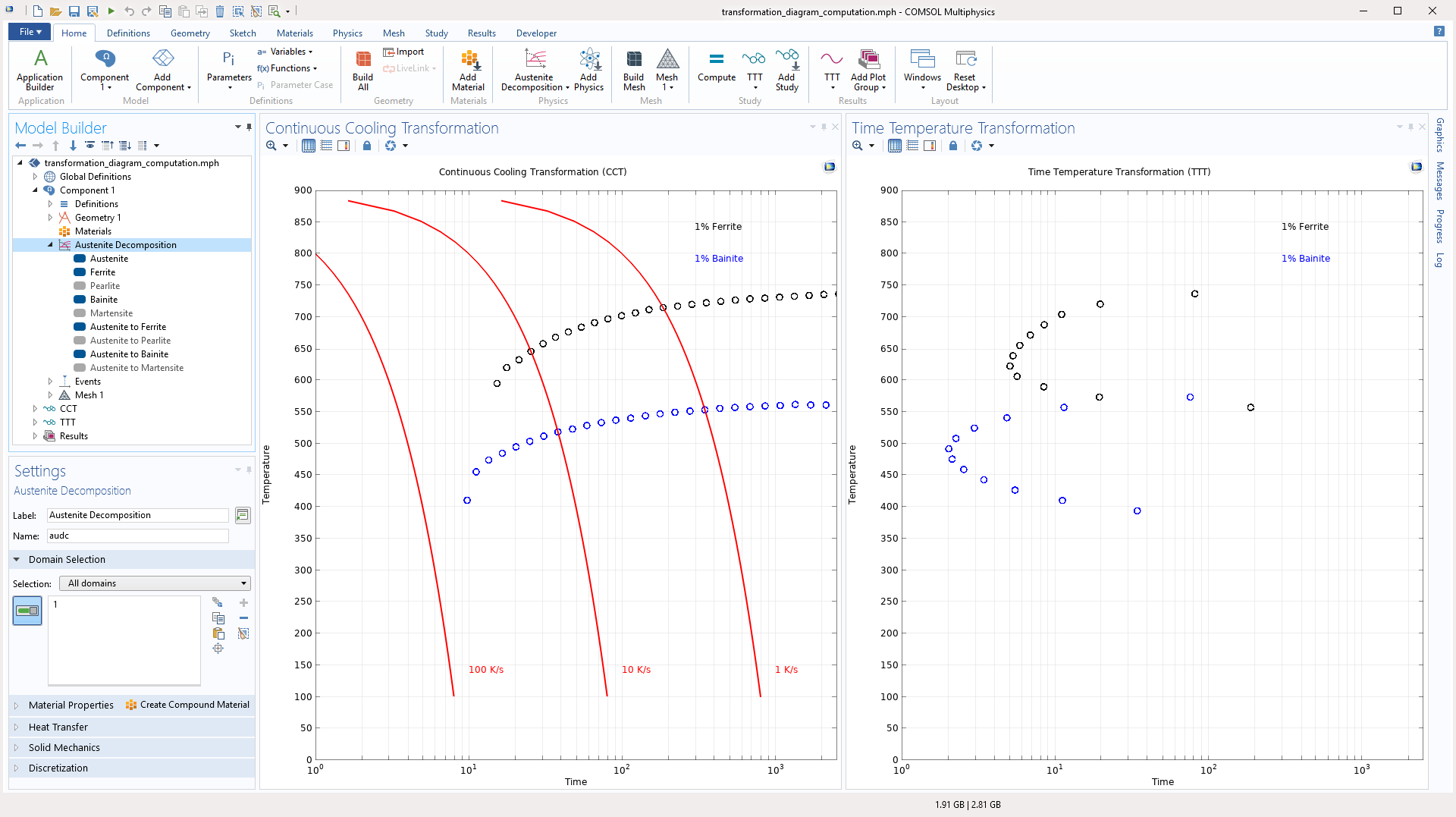

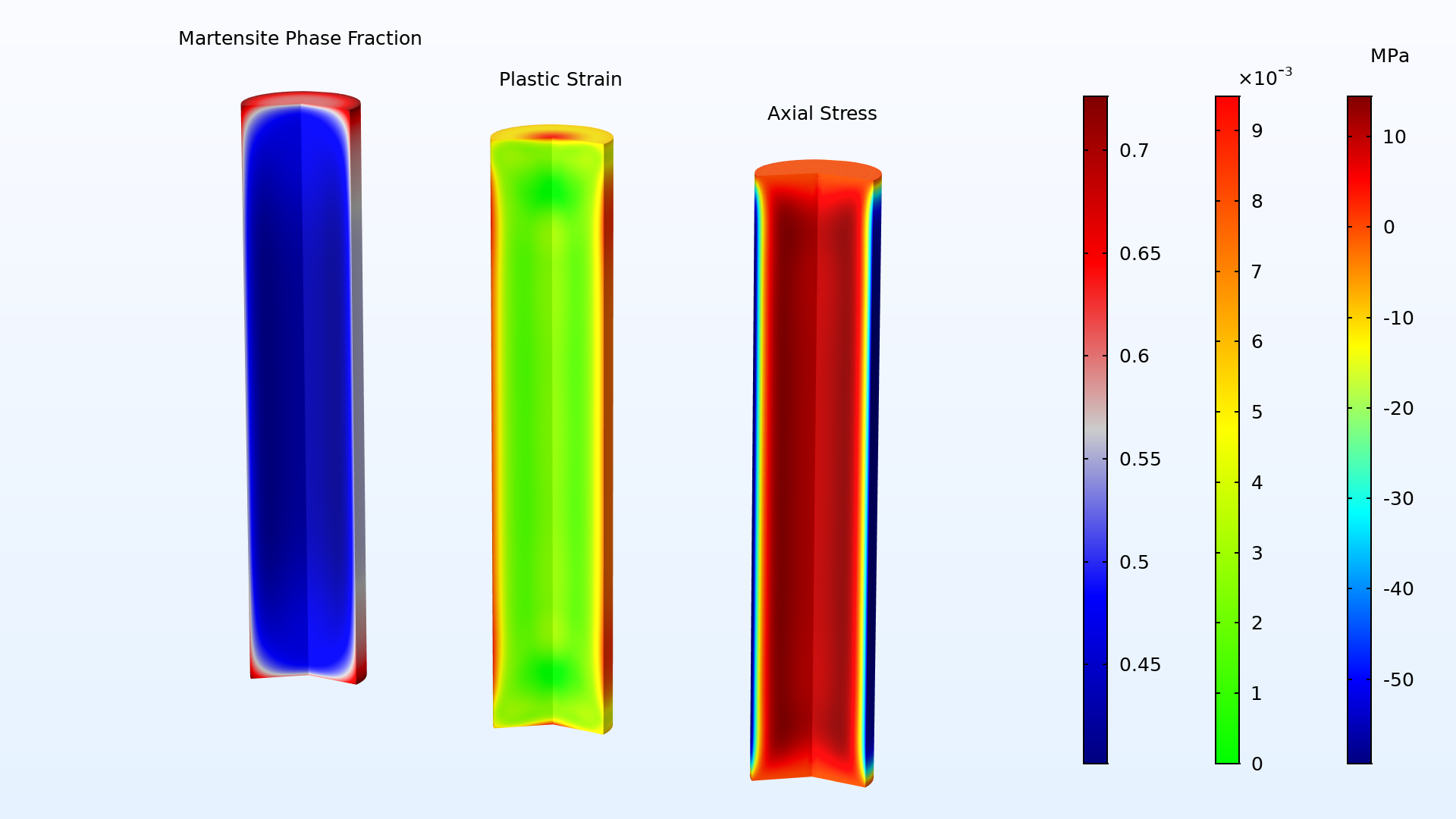

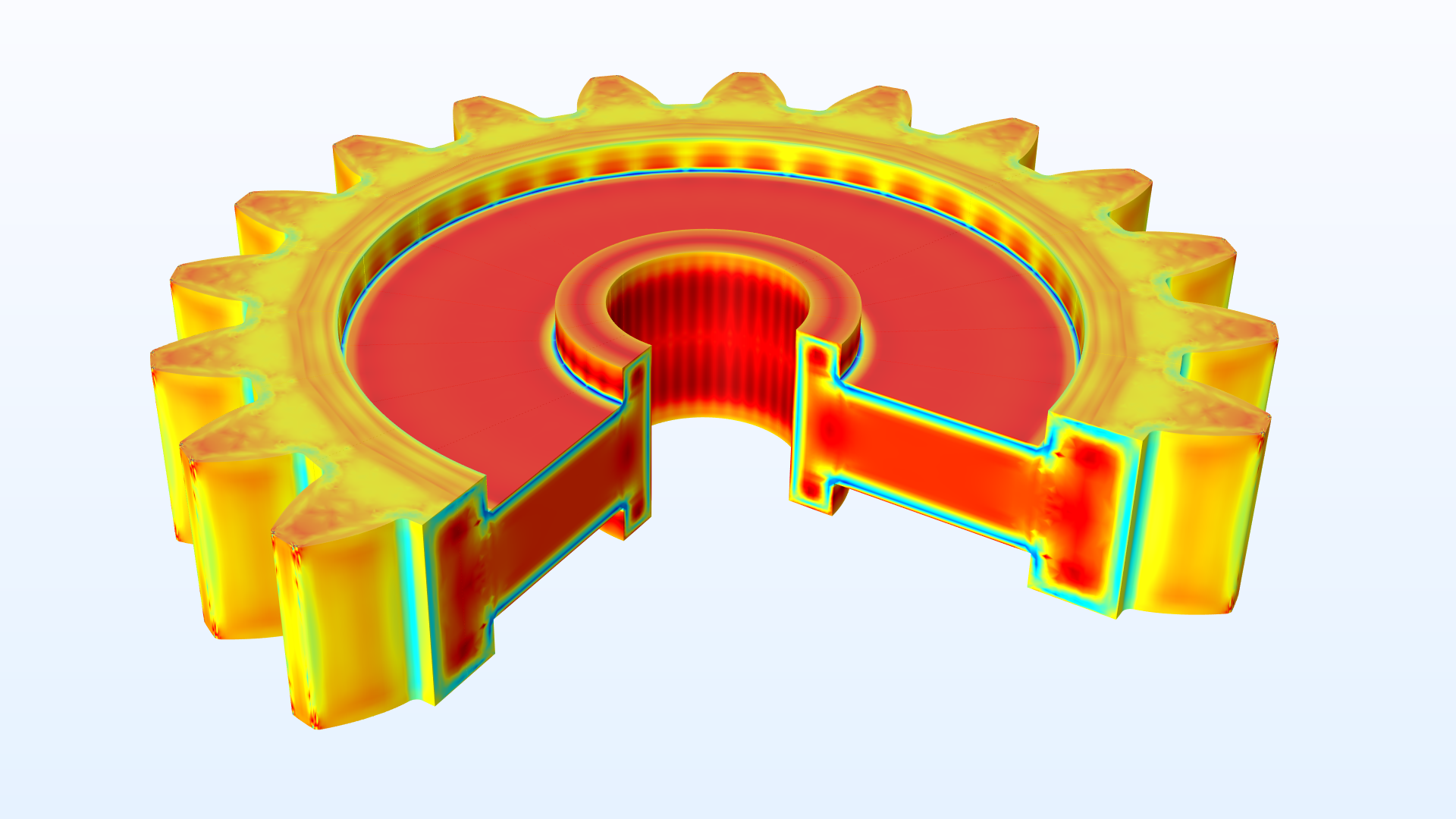

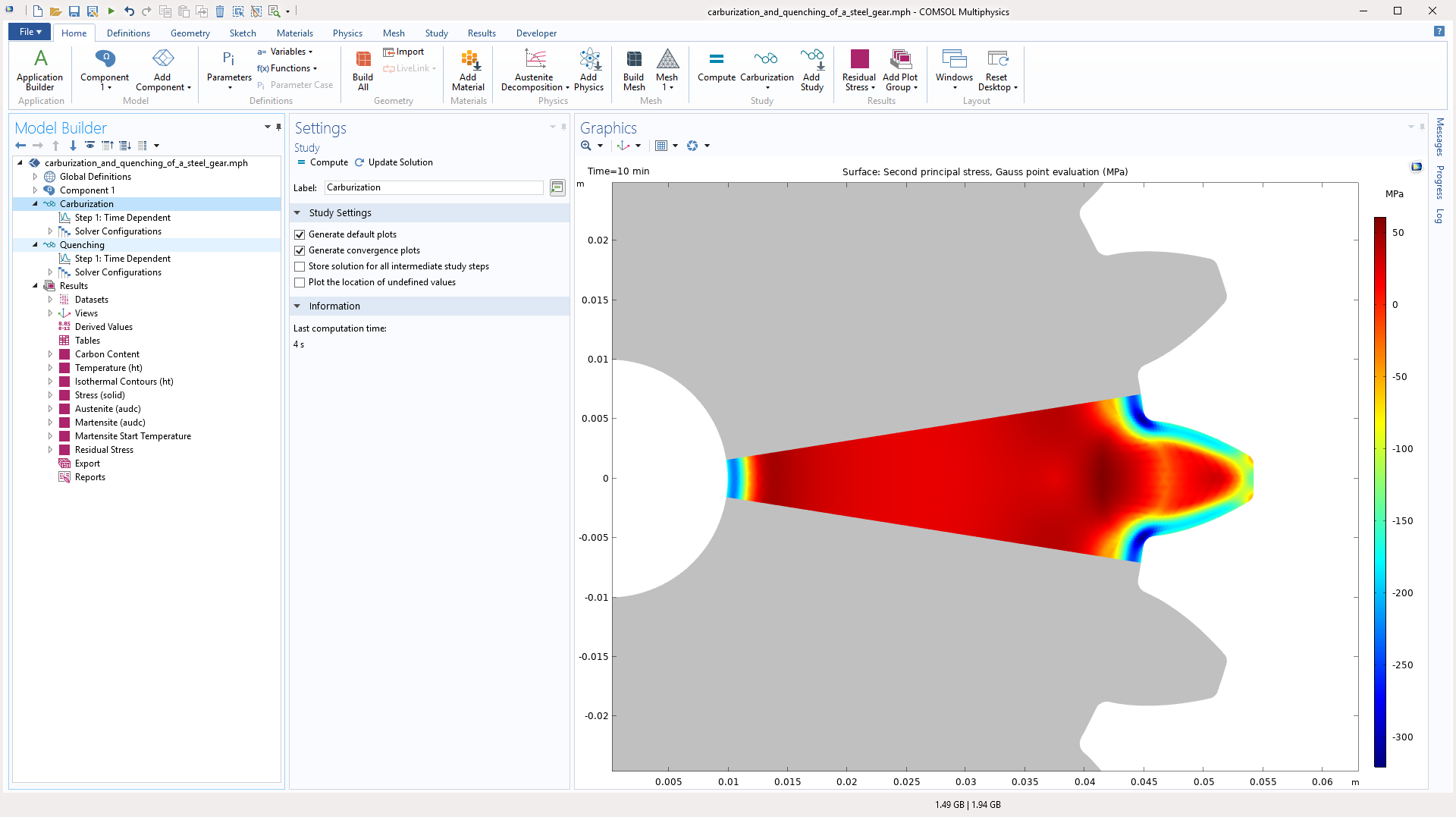

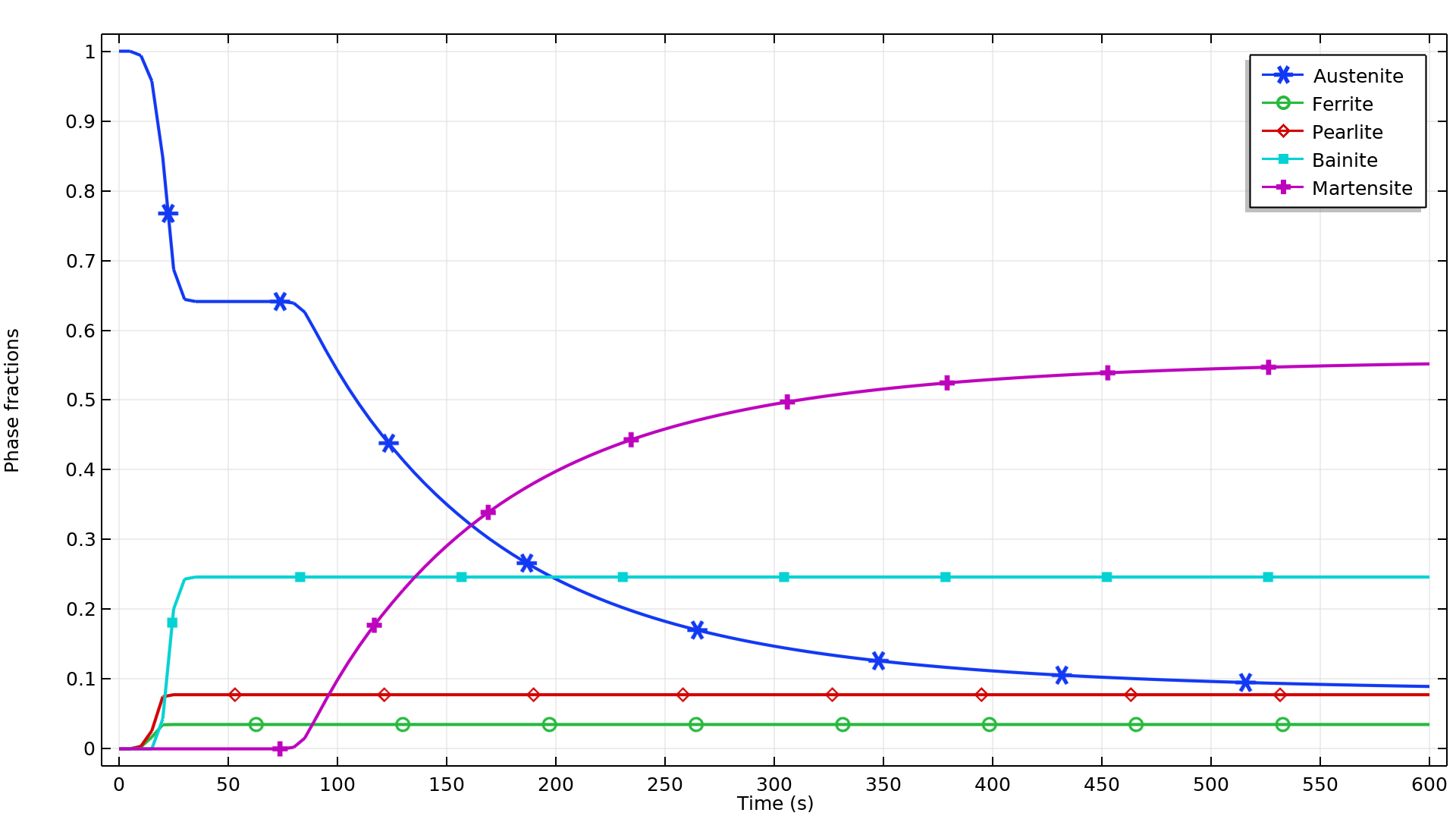

When a material like steel undergoes heating or cooling from an elevated temperature, metallurgical phase transformations may occur. These transformations are sometimes deliberate, as part of the heat treatment of a mechanical component, or introduced inadvertently, as with welding. The metallurgical phases that are present in a component will affect its mechanical and thermal properties, and by optimising the phase composition, you can improve the performance of a component. The Metal Processing Module, an add-on to the COMSOL Multiphysics® software, can be used to simulate metallurgical phase transformations in 3D, 2D, and 2D axisymmetric bodies.

The Metal Processing Module provides a comprehensive set of tools for simulating manufacturing processes like steel quenching, welding, and additive manufacturing. These tools are packaged into physics interfaces, which automatically set up and solve the equations specific to the manufacturing process that you are modelling.

The material properties of metallurgical phases, such as austenite and pearlite, will depend on temperature and plastic strain, among other factors. The effort involved in obtaining material properties for the different metallurgical phases can be significant, and as an option, you can import material properties from the software JMatPro®.

If you add the AC/DC Module, you can perform induction hardening simulations, where you use the calculated temperature field from an induction heating simulation as the input to a quenching simulation.

In order to fully evaluate whether or not the COMSOL Multiphysics® software will meet your requirements, you need to contact us. By talking to one of our sales representatives, you will get personalised recommendations and fully documented examples to help you get the most out of your evaluation and guide you to choose the best license option to suit your needs.

Fill in your contact details and any specific comments or questions, and submit. You will receive a response from a sales representative within one business day.