COMSOL has the best multiphysical simulation capabilities in my experience. Technical support from Elisa at TECHNIC as well as the engineers at COMSOL has been great.

COMSOL is an important part of our research in plasma physics. We use it in the design of plasma systems and it helps us to obtain a greater understanding of the underlying physics. We have always valued the quick support from TECHNIC and COMSOL and it has been a pleasure to work with them.

Comsol has become a valuable part of our design and decision making process. The exceptional flexibility and access to the physics and solvers in Comsol has allowed us to have deeper understanding on thermomechanical solutions. Technic and Comsol have always been quick and helpful to resolve any issues and provide helpful advice on their products.

At Scion we use COMSOL Multiphysics to understand energy processes, such as the interplay of non-linear solid mechanics and heat & mass transfer during biomass compaction, to design new or more efficient processes.

We use COMSOL Multiphysics to design the customised muffler. With it, we can simulate the insertion loss at different spectrum with different muffler designs.

The design and modelling of microelectromechanical systems (MEMS) is a unique engineering discipline. At small length scales, the design of resonators, gyroscopes, accelerometers, and actuators must consider the effects of several physical phenomena in their operation. Consequently, COMSOL Multiphysics is ideally suited for MEMS applications. To this end, the MEMS Module provides predefined user interfaces with associated modelling tools, referred to as physics interfaces, for a variety of coupled physics, including electromagnetic-structure, thermal-structure, or fluid-structure interactions. You can include a variety of damping phenomena in your model: thin-film gas damping, anisotropic loss-factors for solid and piezo materials, anchor damping, and thermoelastic damping. For elastic vibrations and waves, perfectly matched layers (PMLs) provide state-of-the-art absorption of outgoing elastic energy.

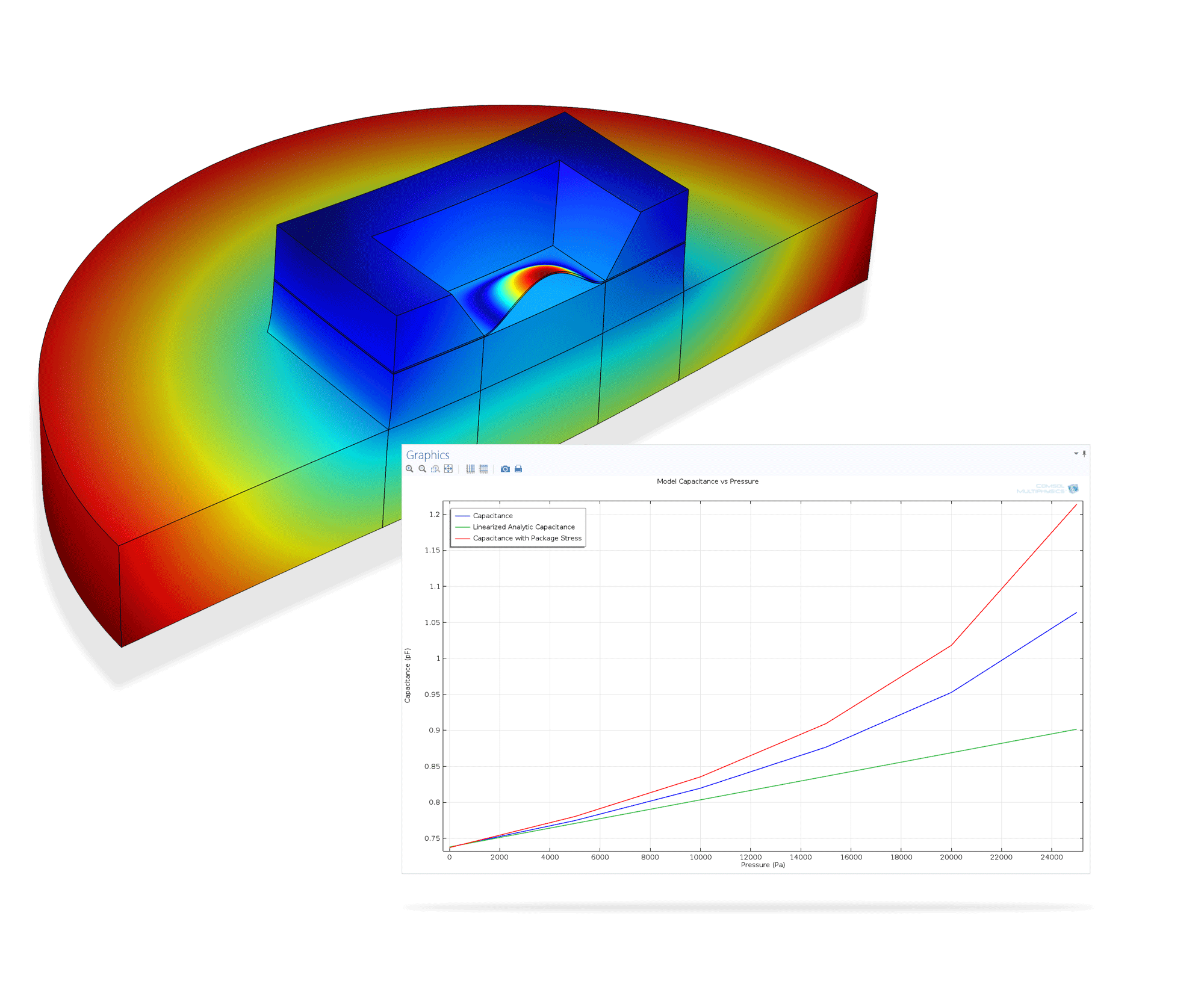

Best-in-class piezoelectric and piezoresistive modelling tools allow for simulations where composite piezo-elastic-dielectric materials can be combined in any imaginable configuration. The MEMS Module includes analyses in the stationary and transient domains, as well as fully-coupled eigenfrequency, parametric, quasi-static, and frequency response analyses. You can easily perform lumped parameter extraction of capacitance, impedance, and admittance, and connect to external electrical circuits via SPICE netlists. Built upon the core capabilities of COMSOL Multiphysics®, the MEMS Module can be used to address virtually any phenomena related to mechanics at the microscale.

To model a MEMS device, you first define the geometry in the software, either by using the native modelling tools of COMSOL, or by importing a CAD model. If you want to import mechanical CAD models, you can do so by using the CAD Import Module or one of the LiveLink™ products for CAD. Electronic layouts can be imported with the aid of the ECAD Import Module. Once the geometry model is defined, the next step is to select appropriate materials and add a suitable physics interface. Initial conditions and boundary conditions are to be set up within the interface. Next, you define the mesh and select a solver. Finally, you visualise the results and process and export the results. All of these steps are accessed from within the COMSOL Desktop®. The solvers are set up automatically with default settings, which are already tuned for each specific interface. However, the advanced user can access and modify low-level solver settings as needed.

You can also integrate your MEMS simulations with Microsoft® Excel®. The LiveLink™ for Excel® allows you to drive simulations from within the Excel® interface as well as import/export of results and materials. If you prefer a scripting environment, the LiveLink™ for MATLAB® makes a series of very powerful MATLAB® compatible commands available when installing COMSOL Multiphysics and MATLAB together. In this manner, COMSOL simulations can be integrated with MATLAB programs. You can export results from a COMSOL model to the MATLAB environment, including inspecting the stiffness and system matrices.

A pressure sensor gives the pressure based on capacitance change, which is related to the deformation of the structure. Deformation depends on the ambient pressure and temperature, on the materials used, and on any initial stresses in the material.

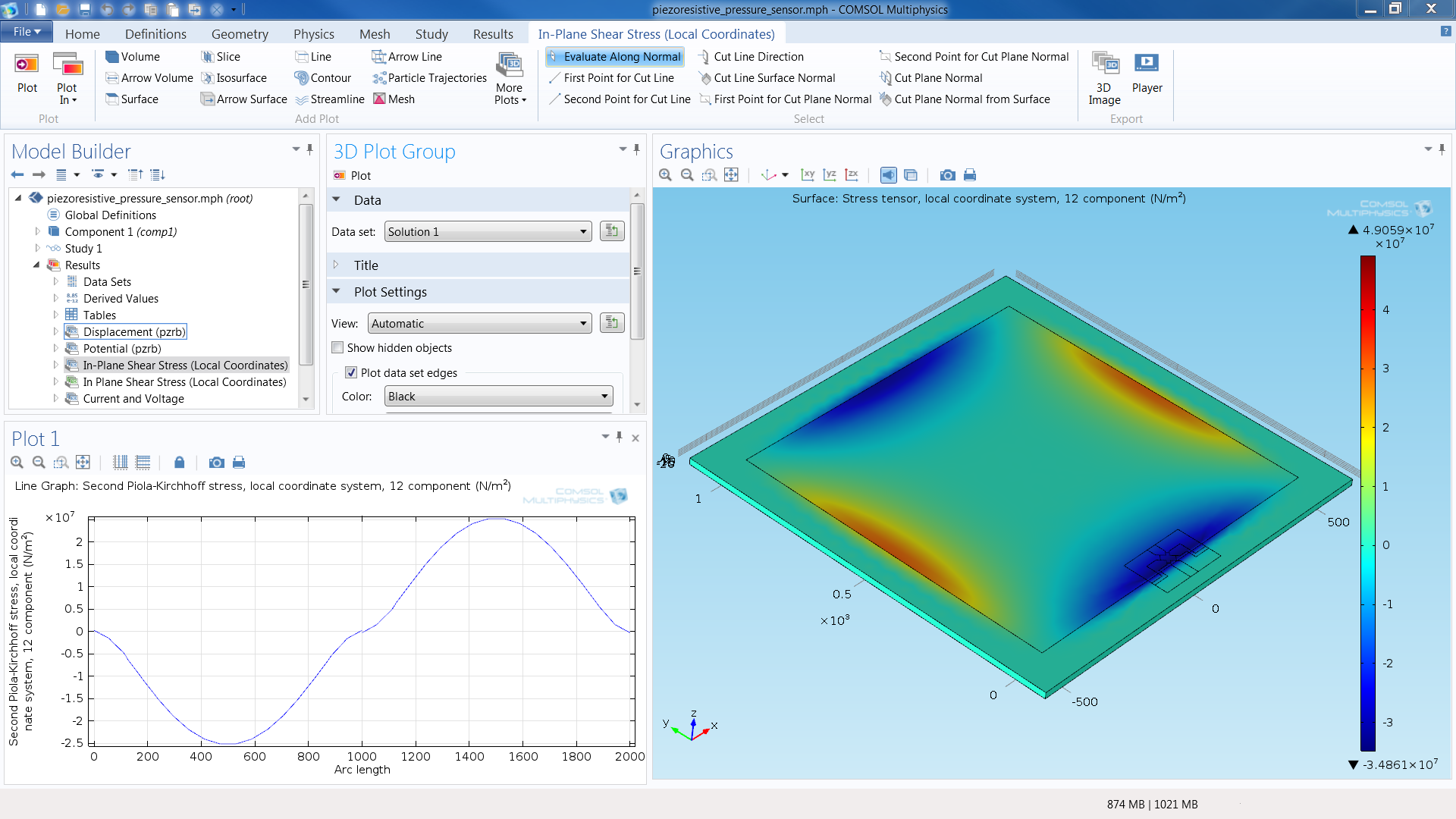

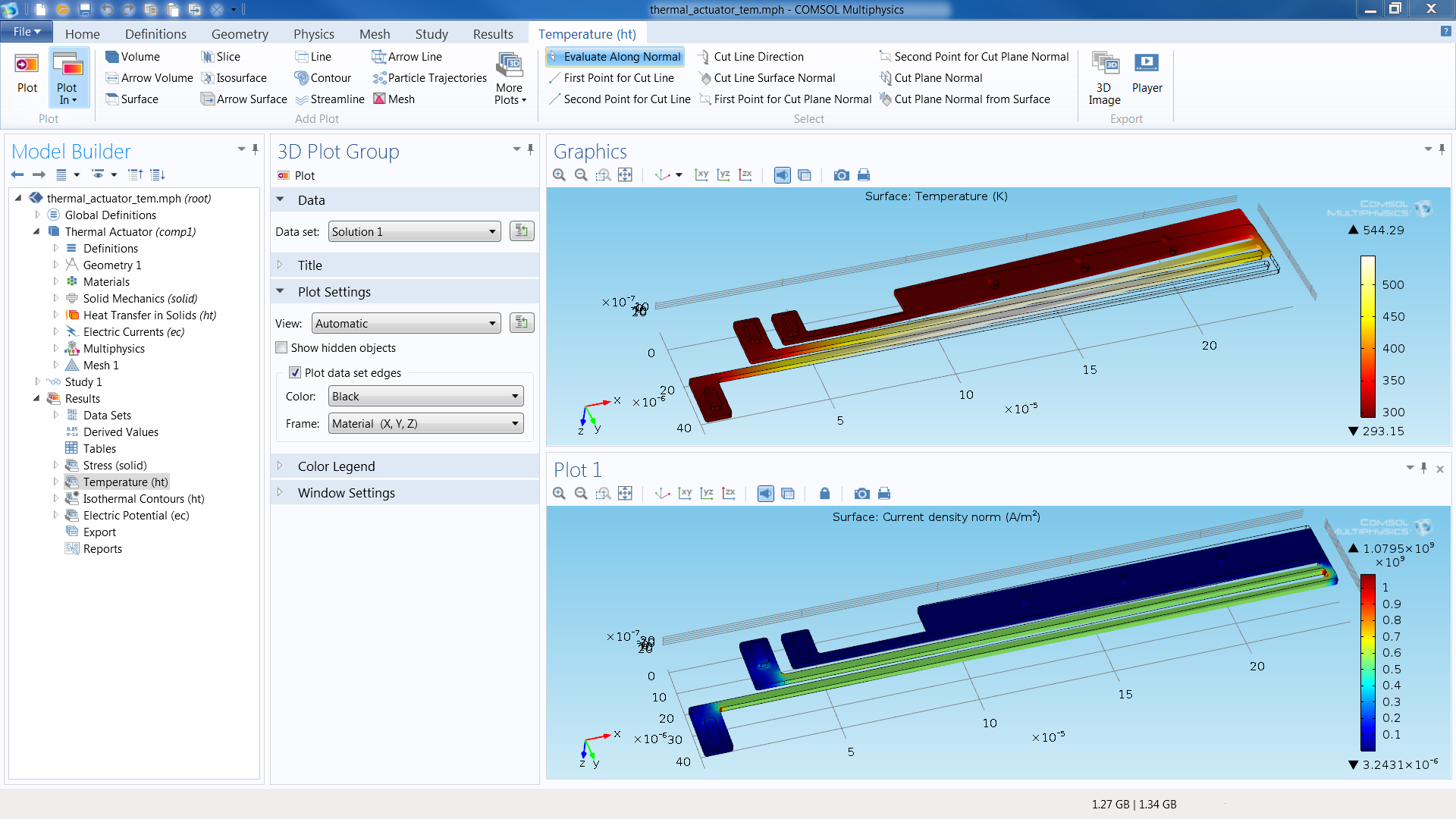

COMSOL’s design emphasises the physics by providing you with the equations solved by each feature and offering you full access to the underlying equation system. There is also tremendous flexibility to add user-defined equations and expressions to the system. For example, to model Joule heating in a structure with temperature-dependent elastic properties, simply enter in the elastic constants as a function of temperature – no scripting or coding is required. When COMSOL compiles the equations, the complex couplings generated by these user-defined expressions are automatically included in the equation system. The equations are then solved using the finite element method and a range of industrial strength solvers. Once a solution is obtained, a vast range of postprocessing tools are available to interrogate the data, and predefined plots are automatically generated to show the device response. COMSOL offers the flexibility to evaluate a wide range of physical quantities, including predefined quantities like temperature, electric field, or stress tensor (available through easy-to-use menus), as well as arbitrary user-defined expressions.

Fluidic MEMS devices, or microfluidic devices, represent an increasingly important area of MEMS. COMSOL provides a separate Microfluidics Module to specifically address these applications, but the MEMS Module does include significant microfluidic functionality for simulating the interaction of MEMS structures with fluids. The Fluid-Structure Interaction (FSI) multiphysics interface combines fluid flow with solid mechanics to capture the interaction between the fluid and the solid structure. Solid Mechanics and Laminar Flow user interfaces model the solid and the fluid, respectively. The FSI couplings appear on the boundaries between the fluid and the solid, and can include both fluid pressure and viscous forces, as well as momentum transfer from the solid to the fluid – bidirectional FSI. The method used for FSI is known as an arbitrary Lagrangian-Eulerian (ALE).

Damping forces from FSI are often important for MEMS devices, frequently leading to a requirement for vacuum packaging. The MEMS module has specialised thin film damping physics interfaces which solve the Reynolds equation to determine the fluid velocity and pressure and the forces on the adjacent surfaces. These interfaces can be used to model squeeze film and slide film damping across a wide range of pressures (rarefaction effects can be included). Thin-film damping is available on arbitrary surfaces in 3D and can be directly coupled to 3D solids.

The Solid Mechanics physics interface is used for stress analysis as well as general linear and nonlinear solid mechanics, solving for the displacements. The MEMS Module includes linear elastic and linear viscoelastic material models, but you can supplement it with the Nonlinear Structural Materials Module to also include nonlinear material models. You can extend the material models with thermal expansion, damping, and initial stress and strain features. In addition, several sources of initial strains are allowed, making it possible to include arbitrary inelastic strain contributions stemming from multiple physical sources. The description of elastic materials in the module includes isotropic, orthotropic, and fully anisotropic materials.

The piezoresistive effect refers to the change in a material’s conductivity that occurs in response to an applied stress. The ease of integration of small piezoresistors with standard semiconductor processes, along with the reasonably linear response of the sensor, has made this technology particularly important in the pressure sensor industry. For modelling piezoresistive sensors, the MEMS Module provides several dedicated physics interfaces for piezoresistivity in solids or shells. When combining the MEMS Module with the Structural Mechanics Module, a piezoresistivity physics interface for thin shells is enabled.

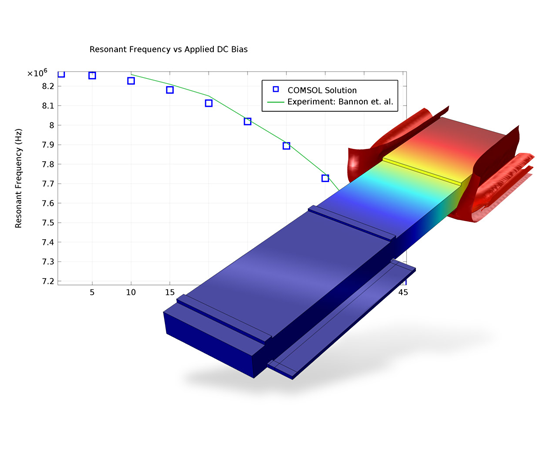

Electrostatic forces scale favourably as the device dimensions are reduced, a fact frequently leveraged in MEMS. A typical application of the MEMS Module within this area is for electrostatically actuated MEMS resonators, which operate with an applied DC bias. The MEMS Module provides a dedicated physics interface for electromechanics that, for MEMS resonators, is used to compute the variation of the resonant frequency with applied DC bias – the frequency decreases with applied potential, due to the softening of the coupled electromechanical system. The small size of the device results in a MHz resonant frequency even for a simple flexural mode. In addition, the favourable scaling of the electromagnetic forces enables efficient capacitive actuation that would not be possible on the macroscale. The Model Library that ships with the MEMS Module has detailed tutorials with step-by-step instructions for electrostatically actuated MEMS resonators. Furthermore, you have the option to use the electromechanics interface to include the effects of isotropic electrostriction.

Piezoelectric forces also scale well as the device dimension is reduced. Furthermore, piezoelectric sensors and actuators are predominantly linear and do not consume DC power in operation. Quartz frequency references can be considered the highest volume MEMS component currently in production – over 1 billion devices are manufactured per year. The physics interfaces of the MEMS Module are uniquely suitable for simulating quartz oscillators as well as a range of other piezoelectric devices.

One of the tutorials shipped with the MEMS Module shows the mechanical response of a thickness shear quartz oscillator together with a series capacitance and its effect on the frequency response. A series capacitance is frequently used to tune or pull the resonance of quartz oscillators, and the MEMS Module allows combining 2D and 3D models with SPICE circuits for such combined simulations.

The Thermoelasticity physics interface is used to model linear thermoelastic materials. It solves for the displacement of the structure and the temperature deviations, and resulting heat transfer induced by the thermoelastic coupling. Thermoelasticity is important in the modelling of high-quality factor MEMS resonators.

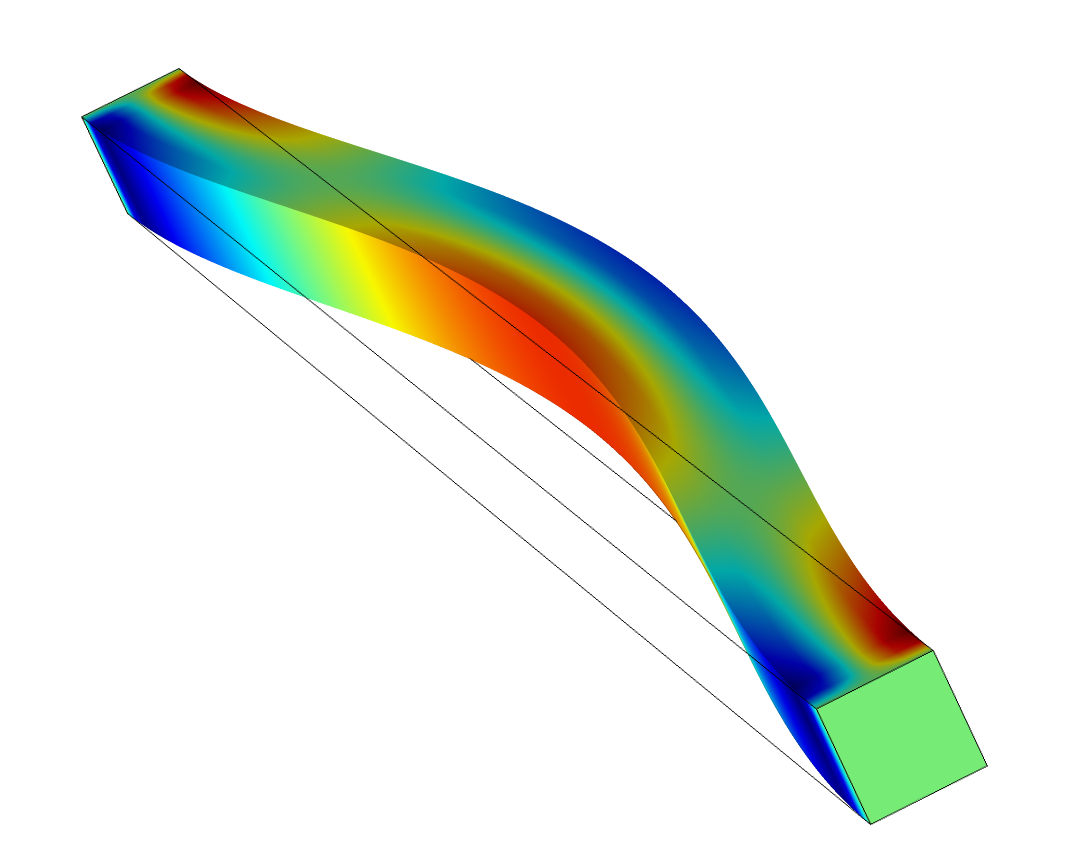

Thermal forces scale favourably in comparison to inertial forces. That makes microscopic thermal actuators fast enough to be useful on the microscale, although thermal actuators are typically slower than capacitive or piezoelectric actuators. Thermal actuators are also easy to integrate with semiconductor processes, although they usually consume large amounts of power compared to their electrostatic and piezoelectric counterparts. The MEMS Module can be used for Joule heating with thermal stress simulations that include details of the distribution of resistive losses. Thermal effects also play an important role in the manufacture of many commercial MEMS technologies with thermal stresses in deposited thin films that are critical for many applications. The MEMS Module includes dedicated physics interfaces for thermal stress computations with extensive postprocessing and visualisation capabilities, including stress and strain fields, principal stress and strain, equivalent stress, displacement fields, and more.

In order to fully evaluate whether or not the COMSOL Multiphysics® software will meet your requirements, you need to contact us. By talking to one of our sales representatives, you will get personalised recommendations and fully documented examples to help you get the most out of your evaluation and guide you to choose the best license option to suit your needs.

Fill in your contact details and any specific comments or questions, and submit. You will receive a response from a sales representative within one business day.