COMSOL has the best multiphysical simulation capabilities in my experience. Technical support from Elisa at TECHNIC as well as the engineers at COMSOL has been great.

COMSOL is an important part of our research in plasma physics. We use it in the design of plasma systems and it helps us to obtain a greater understanding of the underlying physics. We have always valued the quick support from TECHNIC and COMSOL and it has been a pleasure to work with them.

Comsol has become a valuable part of our design and decision making process. The exceptional flexibility and access to the physics and solvers in Comsol has allowed us to have deeper understanding on thermomechanical solutions. Technic and Comsol have always been quick and helpful to resolve any issues and provide helpful advice on their products.

At Scion we use COMSOL Multiphysics to understand energy processes, such as the interplay of non-linear solid mechanics and heat & mass transfer during biomass compaction, to design new or more efficient processes.

We use COMSOL Multiphysics to design the customised muffler. With it, we can simulate the insertion loss at different spectrum with different muffler designs.

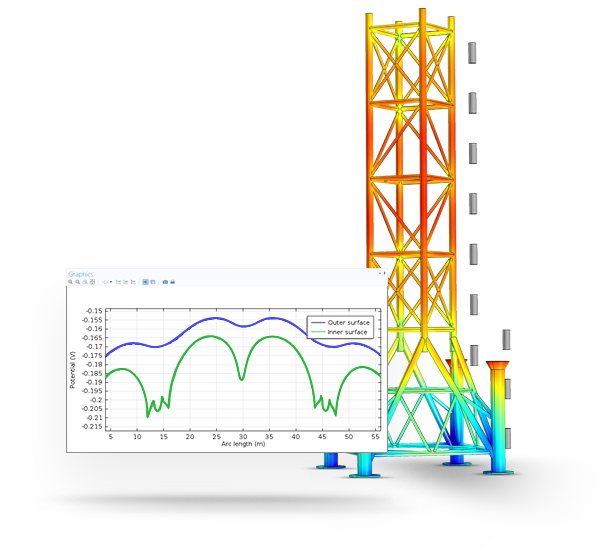

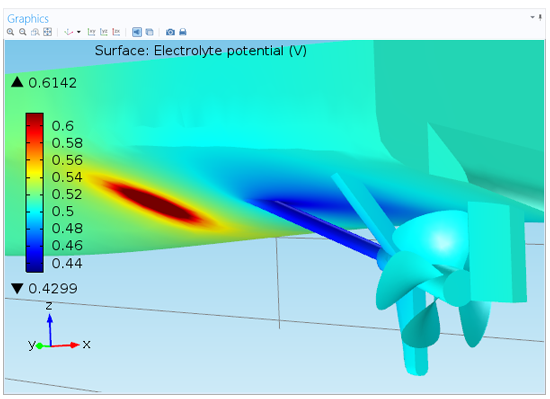

Most corrosion occurs due to electrochemical reaction processes taking place underwater and in wet or humid environments. The Corrosion Module allows engineers and scientists to investigate these processes, gain an understanding of the extent to which corrosion could occur over the lifetime of a structure, and implement preventative measures to inhibit electrochemical corrosion, in order to protect their structures. The module can be used to simulate corrosion at the microscale in order to investigate the fundamental mechanisms, and at larger scales to determine how to protect massive or long-ranging structures from corroding.

The Corrosion Module also allows you to design effective corrosion protection systems. This includes the simulation of Impressed Cathodic Current Protection (ICCP), sacrificial anodes, and anodic protection, where anodic current is impressed on corroding material to enforce passivation.

By using the Corrosion Module to investigate the specific protection mechanisms at the microscale, you can extract parameters that may be used to simulate larger structure, for example hydroxide film growth on protected structures. You can import CAD files containing your designs in COMSOL Multiphysics, and then set up the description of the protection process. Upon identifying regions in your structure that are susceptible to accelerated corrosion, you can specify the placement of sacrificial anodes, and where cathodic or anodic protection currents should be impressed.

Another application of the module is to estimate the effect of stray currents on the corrosion of buried structures or structures under water. You can then also use the module to optimise the positioning of protective electrodes to avoid this corrosion mechanism. When correctly designed, these electrodes mediate the uptake of stray currents without corroding the structure placed close to a stray current source, e.g. a railroad.

A steel structure immersed in seawater is protected from corrosion through 40 sacrificial anodes. This example models the potential distribution at the surface of the protected structure assuming a constant limiting current for oxygen reduction at the protected surface.

The Corrosion Module also allows you to design effective corrosion protection systems. This includes the simulation of Impressed Cathodic Current Protection (ICCP), sacrificial anodes, and anodic protection, where anodic current is impressed on corroding material to enforce passivation.

By using the Corrosion Module to investigate the specific protection mechanisms at the microscale, you can extract parameters that may be used to simulate larger structure, for example hydroxide film growth on protected structures. You can import CAD files containing your designs in COMSOL Multiphysics, and then set up the description of the protection process. Upon identifying regions in your structure that are susceptible to accelerated corrosion, you can specify the placement of sacrificial anodes, and where cathodic or anodic protection currents should be impressed.

Another application of the module is to estimate the effect of stray currents on the corrosion of buried structures or structures under water. You can then also use the module to optimise the positioning of protective electrodes to avoid this corrosion mechanism. When correctly designed, these electrodes mediate the uptake of stray currents without corroding the structure placed close to a stray current source, e.g. a railroad.

The impact corrosion can have on a structure over time can be downright catastrophic. As corrosion removes material from a structure, it may compromise its structural integrity.

In some cases, you may want to do a structural analysis in combination with corrosion analysis to see which parts of the structure are subjected to high stresses and strains. Corrosion in these parts may be devastating, so you want to make sure that these parts are protected. To understand the corrosion effects and to optimise your corrosion protection design, you can combine the Corrosion Module with the Structural Mechanics Module. This is thanks to the extensive power of COMSOL Multiphysics, which allows you to directly couple models built in one module with any other module.

In other cases, turbulent and multiphase flow may need to be combined with transport of chemical species. You can then use the CFD Module in combination with the mass transport interfaces in the Corrosion Module to obtain accurate mass transport descriptions.

In order to fully evaluate whether or not the COMSOL Multiphysics® software will meet your requirements, you need to contact us. By talking to one of our sales representatives, you will get personalised recommendations and fully documented examples to help you get the most out of your evaluation and guide you to choose the best license option to suit your needs.

Fill in your contact details and any specific comments or questions, and submit. You will receive a response from a sales representative within one business day.