COMSOL has the best multiphysical simulation capabilities in my experience. Technical support from Elisa at TECHNIC as well as the engineers at COMSOL has been great.

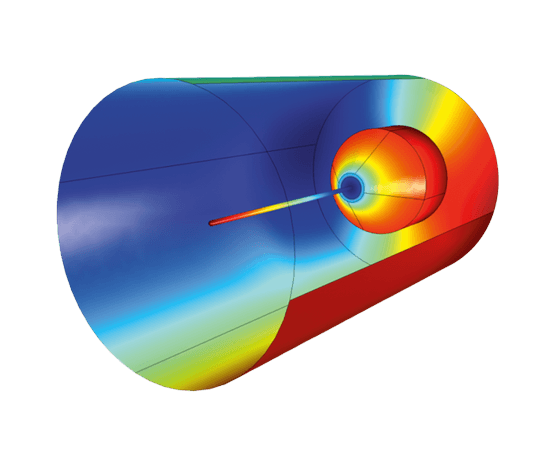

COMSOL is an important part of our research in plasma physics. We use it in the design of plasma systems and it helps us to obtain a greater understanding of the underlying physics. We have always valued the quick support from TECHNIC and COMSOL and it has been a pleasure to work with them.

Comsol has become a valuable part of our design and decision making process. The exceptional flexibility and access to the physics and solvers in Comsol has allowed us to have deeper understanding on thermomechanical solutions. Technic and Comsol have always been quick and helpful to resolve any issues and provide helpful advice on their products.

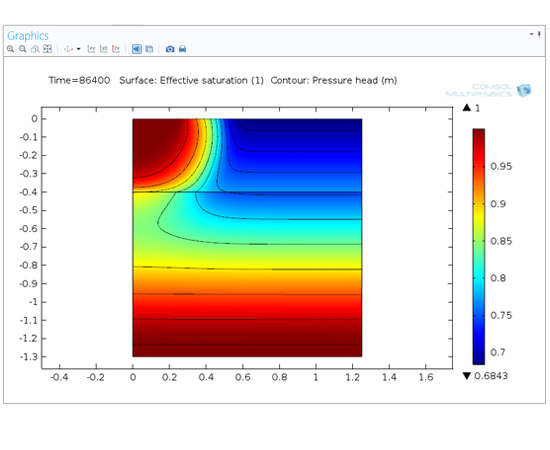

At Scion we use COMSOL Multiphysics to understand energy processes, such as the interplay of non-linear solid mechanics and heat & mass transfer during biomass compaction, to design new or more efficient processes.

We use COMSOL Multiphysics to design the customised muffler. With it, we can simulate the insertion loss at different spectrum with different muffler designs.

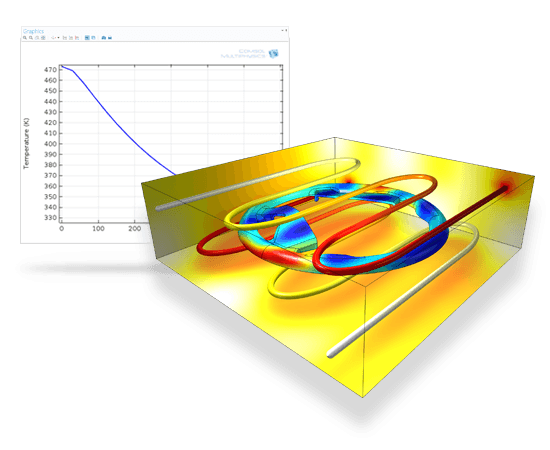

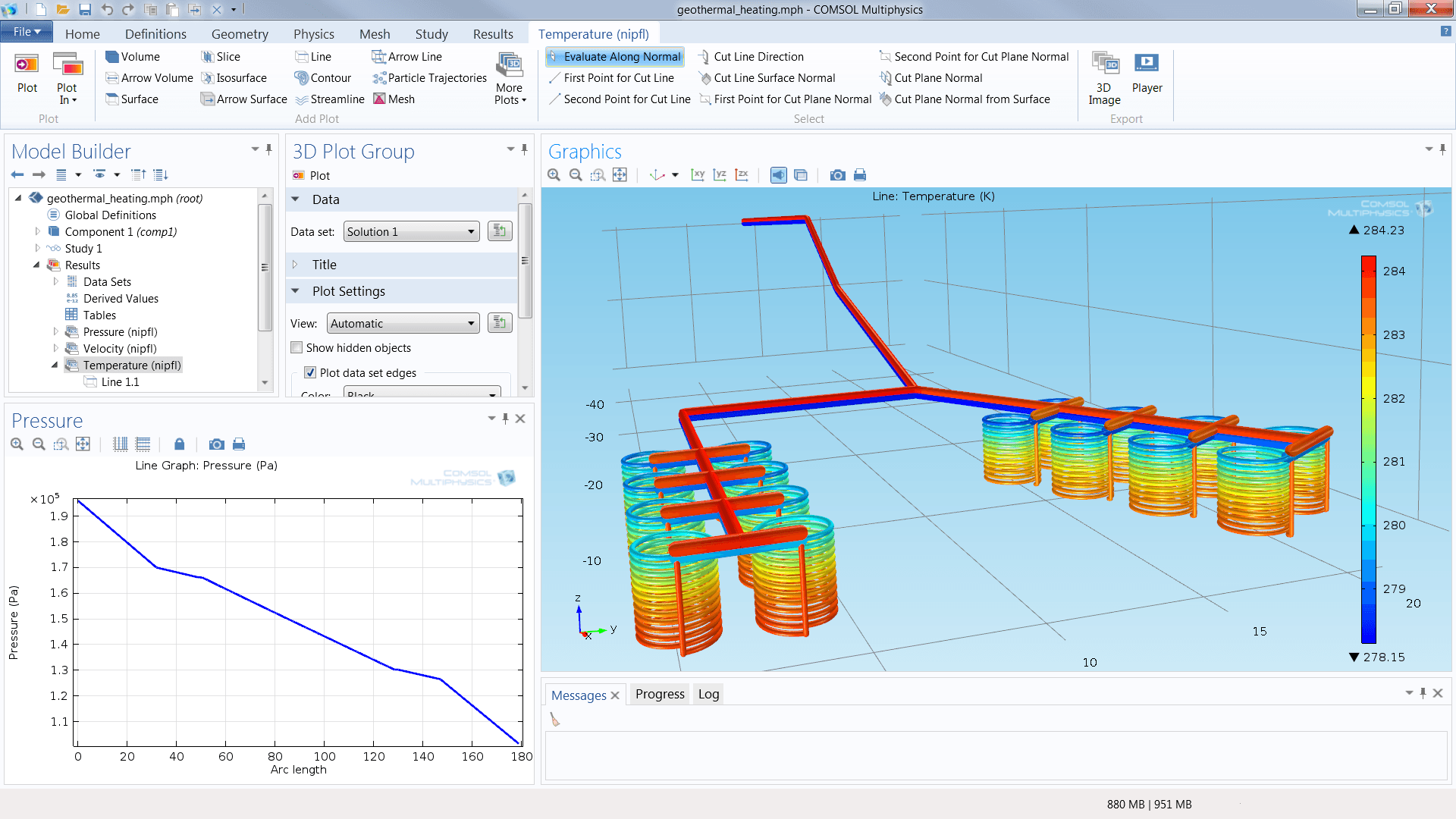

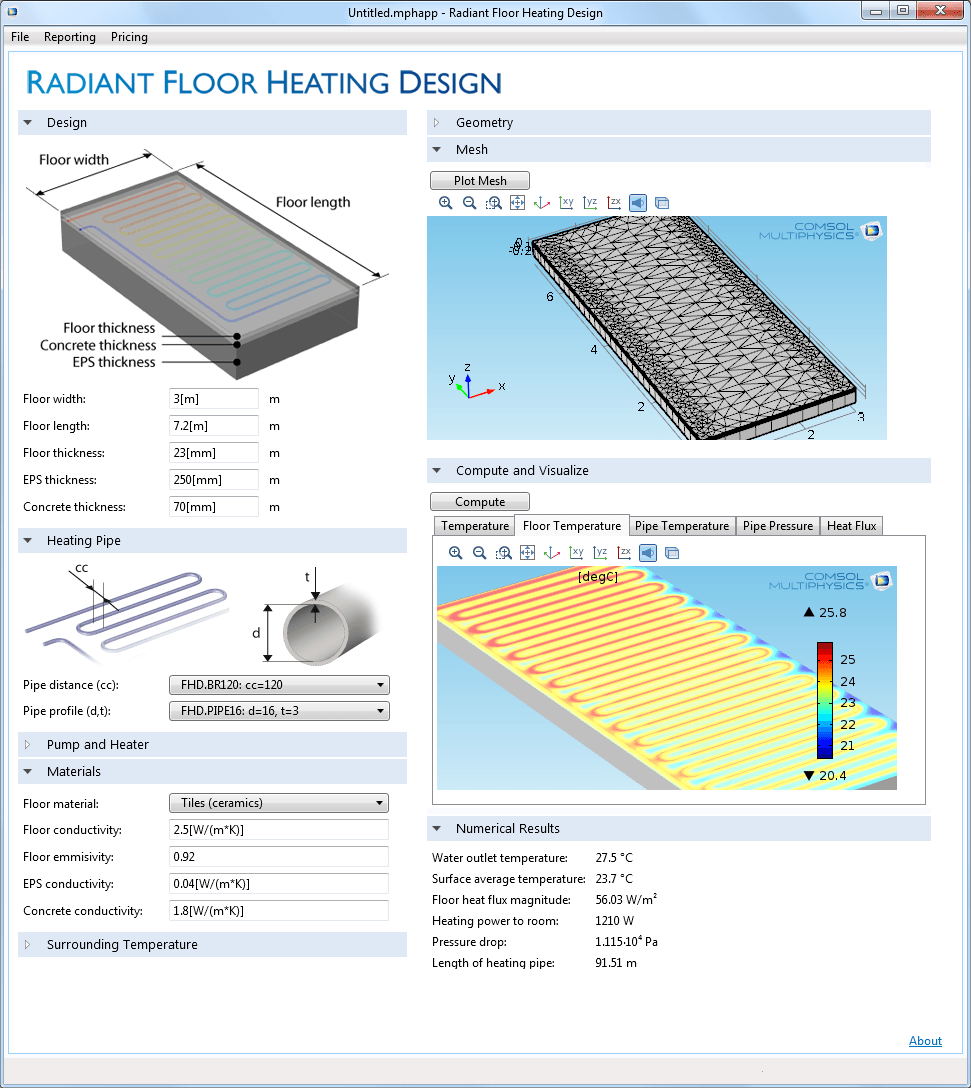

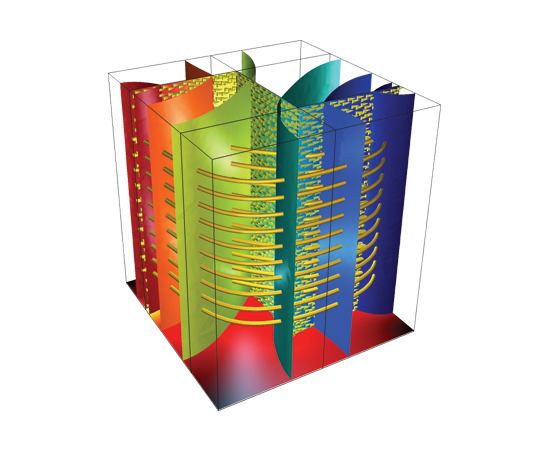

The Pipe Flow Module is used for simulations of fluid flow, heat and mass transfer, hydraulic transients, and acoustics in pipe and channel networks. It can be easily integrated with any of the other modules in the COMSOL® Product Suite for modelling the effects piping has on larger entities, such as cooling pipes in engine blocks or feeding and product channels connected to vessels. This allows for the conservation of computational resources in your overall modelling of processes that consist of piping networks, while still allowing you to consider a full description of your process variables within these networks. Pipe flow simulations provide the velocity, pressure, material concentrations, and temperature distributions along pipes and channels, while it can also simulate acoustic wave propagation and the water hammer effect.

The Pipe Flow Module is suitable for modelling incompressible flow in pipes and channels whose lengths are large enough that flow can be considered fully developed. With this assumption it uses edge elements, solving for the tangential cross-section averaged velocity along the edges, to avoid meshing the cross section of the pipe with a full 3D mesh. This means that the modelled variables are averaged in the pipe's cross sections and vary only along the length of the pipe. Built-in expressions for Darcy friction factors cover the entire flow regime including laminar and turbulent flow, Newtonian and non-Newtonian fluids, different cross-sectional shapes or geometries, and a wide range of relative surface roughness values. These can be varied according to their position in the network, or directly related to the variables you are modelling.

Friction is not the only contribution to pressure loss in pipe networks. The Pipe Flow Module also considers the effects of bends, contractions, expansions, T-junctions, and valves that are computed through an extensive library of industry standard loss coefficients, while pumps are also available as flow-inducing devices. As with any physics interface in the COMSOL Product Suite, you can freely manipulate the underlying equations, add your own source or sink terms, and express physical property as functions of any model variable. COMSOL Multiphysics® also allows you to bring in data to describe a certain material property or process parameter, as well as subroutines written in MATLAB®.

Cooling of a steering wheel injection mold: Non-isothermal pipe flow is fully coupled to the heat transfer simulation of the mold and polyurethane part.

The Pipe Flow Module features a number of physics interfaces for the simulation of pipe flow and processes dependent upon it:

* Requires the Acoustics Module.

In order to fully evaluate whether or not the COMSOL Multiphysics® software will meet your requirements, you need to contact us. By talking to one of our sales representatives, you will get personalised recommendations and fully documented examples to help you get the most out of your evaluation and guide you to choose the best license option to suit your needs.

Fill in your contact details and any specific comments or questions, and submit. You will receive a response from a sales representative within one business day.