COMSOL has the best multiphysical simulation capabilities in my experience. Technical support from Elisa at TECHNIC as well as the engineers at COMSOL has been great.

COMSOL is an important part of our research in plasma physics. We use it in the design of plasma systems and it helps us to obtain a greater understanding of the underlying physics. We have always valued the quick support from TECHNIC and COMSOL and it has been a pleasure to work with them.

Comsol has become a valuable part of our design and decision making process. The exceptional flexibility and access to the physics and solvers in Comsol has allowed us to have deeper understanding on thermomechanical solutions. Technic and Comsol have always been quick and helpful to resolve any issues and provide helpful advice on their products.

At Scion we use COMSOL Multiphysics to understand energy processes, such as the interplay of non-linear solid mechanics and heat & mass transfer during biomass compaction, to design new or more efficient processes.

We use COMSOL Multiphysics to design the customised muffler. With it, we can simulate the insertion loss at different spectrum with different muffler designs.

Many materials have a nonlinear stress-strain relationship, particularly at higher stress and strain levels. When analysing objects made of such materials, you need to account for nonlinearities in the material properties. The Nonlinear Structural Materials Module, an add-on to the Structural Mechanics Module and the COMSOL Multiphysics® software, makes it easy to incorporate these effects by offering additional material models such as hyperelasticity, elastoplasticity, viscoplasticity, and creep.

The Nonlinear Structural Materials Module augments the functionality of structural mechanics models in COMSOL Multiphysics®. You can customise structural analyses for your unique needs by combining the built-in material models and even defining your own models based on, for example, stress or strain invariants. You can create your own flow rules and creep laws, as well as your own strain energy density functions for hyperelasticity.

The functionality for modelling nonlinear materials augments all of the structural analyses available with COMSOL Multiphysics®. This extends to the other structural mechanics add-on modules: the Composite Materials Module, the Fatigue Module, the Multibody Dynamics Module, and the Rotordynamics Module; as well as the MEMS Module. Additionally, as with every COMSOL Multiphysics® add-on module, there are built-in multiphysics capabilities for modelling thermal effects and fluid-structure interaction, for example.

The Geomechanics Module, a similar but separate add-on to the Structural Mechanics Module, is specifically developed for materials common in geotechnical applications such as soils and rocks.

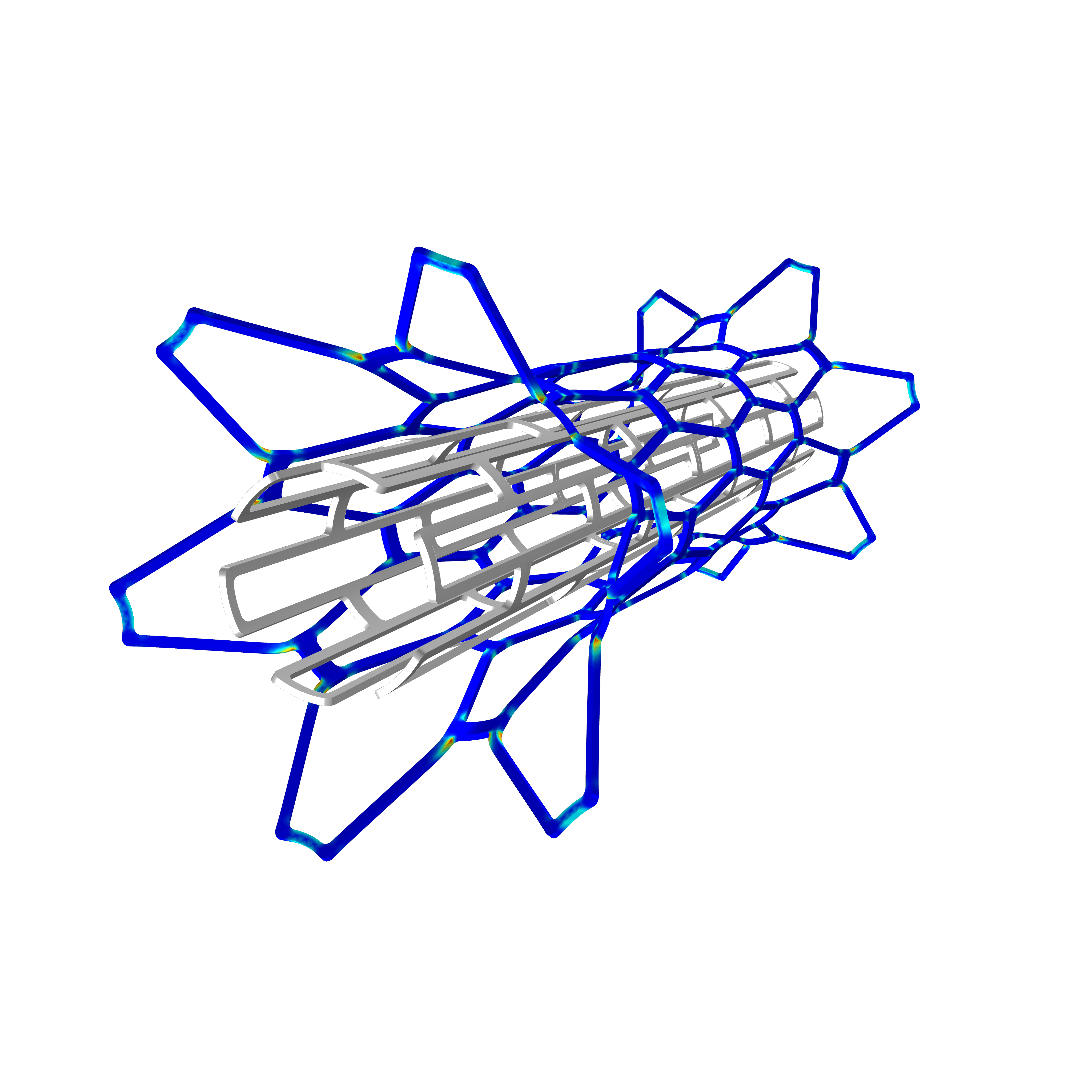

The Nonlinear Structural Materials Module contains dozens of material models to help you model a wide range of solid materials. Hyperelasticity is commonly used for rubber and biological tissue; the plasticity and creep models are predominantly used for metals; porous plasticity is intended for powder compaction (metals as well as pharmaceutical pills); the damage models are mainly applicable for brittle materials, like ceramics; and shape memory alloy models are useful for materials like nitinol.

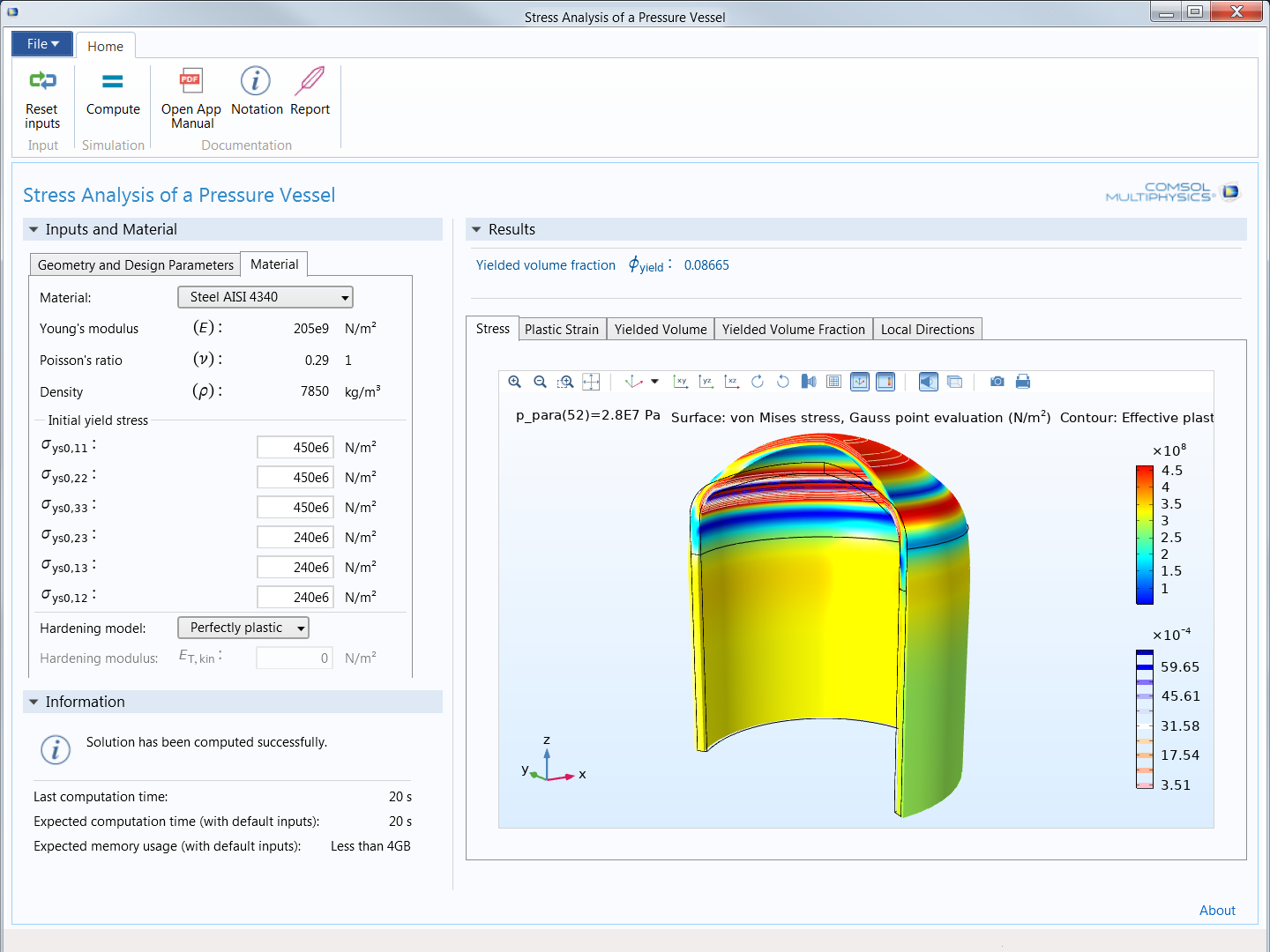

The Application Builder, included in COMSOL Multiphysics®, enables you to build simulation applications that further simplify the simulation workflow by enabling you to restrict the inputs and control the outputs of your model so that your colleagues can run their own analyses. Working with specific material models, this functionality is especially useful for testing how different materials affect a simulation.

With specialised applications, you can easily change a design parameter, such as a geometrical dimension or material property, and test it as many times as you need without having to know the inner workings of the software. You can use applications to run your own tests more quickly or distribute applications to other members of your team to run their own tests, further freeing up your time and resources for other projects.

The process is simple:

You can expand the capabilities of simulation throughout your team, organisation, classroom, or customer base by building and using simulation applications.

In order to fully evaluate whether or not the COMSOL Multiphysics® software will meet your requirements, you need to contact us. By talking to one of our sales representatives, you will get personalised recommendations and fully documented examples to help you get the most out of your evaluation and guide you to choose the best license option to suit your needs.

Fill in your contact details and any specific comments or questions, and submit. You will receive a response from a sales representative within one business day.